Chengdu Xinxiwang is a high-tech enterprise that provides overall solutions for machine vision. The following will lead you to analyze the help and opportunities brought by three-dimensional machine vision inspection solutions for automotive, electronics, food and beverage, consumption, logistics and other industries, and help enterprises to resume production.

Automobile industry

Cover more comprehensive 3D vision solutions

From assembly to final inspection, almost all systems and components are manufactured using machine vision technology, including gasoline-powered, hybrid or electric vehicles. Cognex 3D machine vision systems enable automotive parts manufacturers and automotive assembly plants to achieve superior quality, safety and meet their production goals.

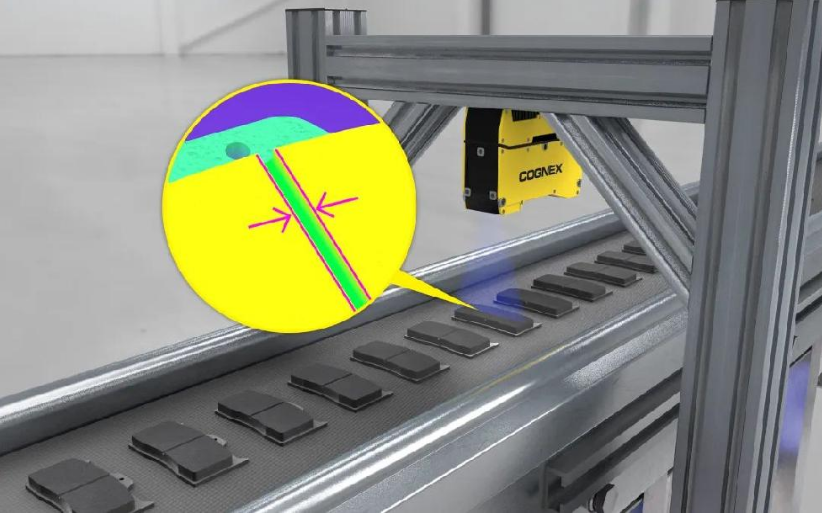

1, brake pad detection

Check brake pad clearance width and check bevel Angle.

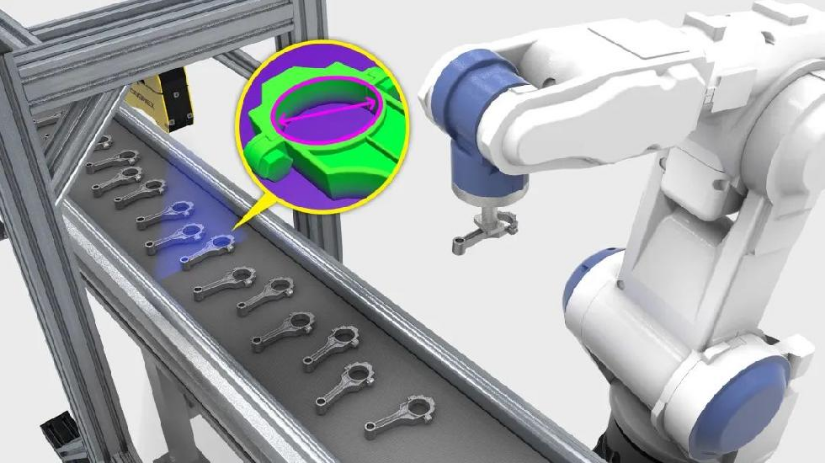

2. Connecting rod detection and positioning

Use PatMax3D to locate the connecting rod on the belt and measure the dimensions to ensure there are no parts defects.

Electronic product industry

Guide, detect, align and recognize with 3D machine vision

Electronics manufacturers and suppliers rely on Cognex's machine vision solutions to solve the most challenging production and packaging problems while meeting stringent safety and quality requirements. Cognex laser profilers and 3D vision systems meet the most demanding application requirements for electronic materials, semiconductors, components, integrated circuit (IC) packages and finished electronic devices. Driven by powerful vision technology and powerful hardware, Cognex tools eliminate defects, verify assembly, and track and capture information throughout the production cycle to achieve the highest quality, high yield, and traceability.

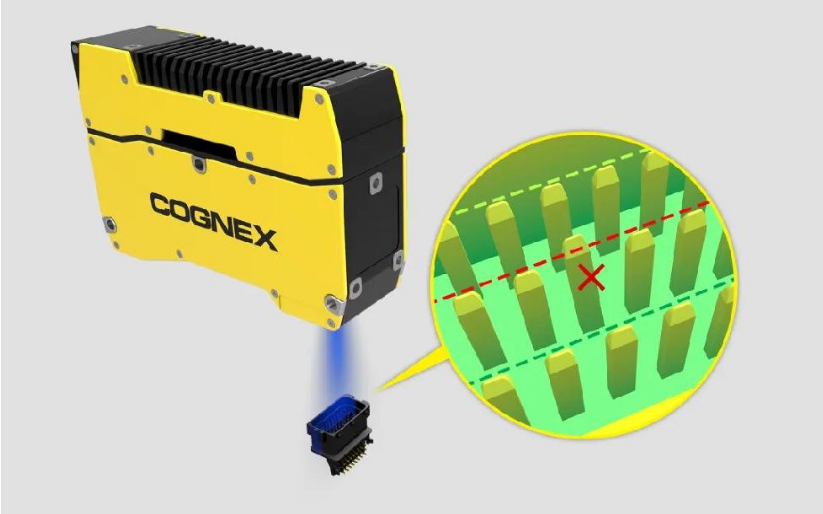

1. interface pin height detection

Check whether the number of pins on the interface is correct, and ensure that the pins are in the correct position and are not damaged or tilted.

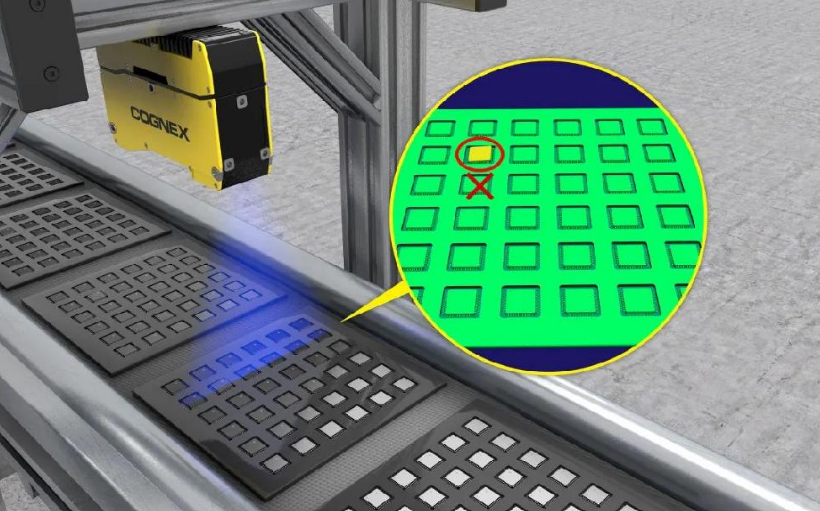

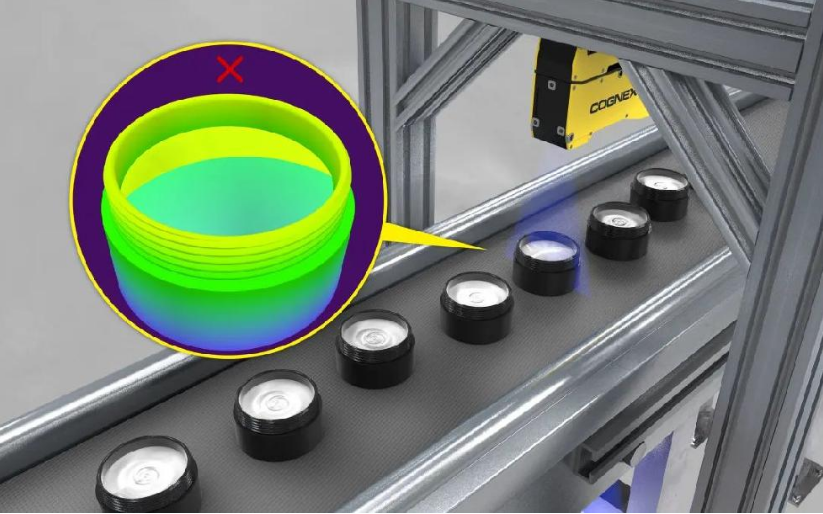

2. Check the flatness of tray

Determine whether the chip is correctly positioned in the tray by measuring its position and flatness.

The food and beverage industry

Protect your customers and your brand with 3D machine vision

With lean operations and thin margin sales, it is increasingly challenging for the food and beverage industry to face pressure to optimize overall equipment efficiency without compromising quality. Successful manufacturers employ machine vision solutions to minimize downtime and consistently deliver safe, high-quality products. With a variety of 3D machine vision systems to choose from, Cognex Solutions help food and beverage manufacturers solve some of their most challenging inspection and verification applications.

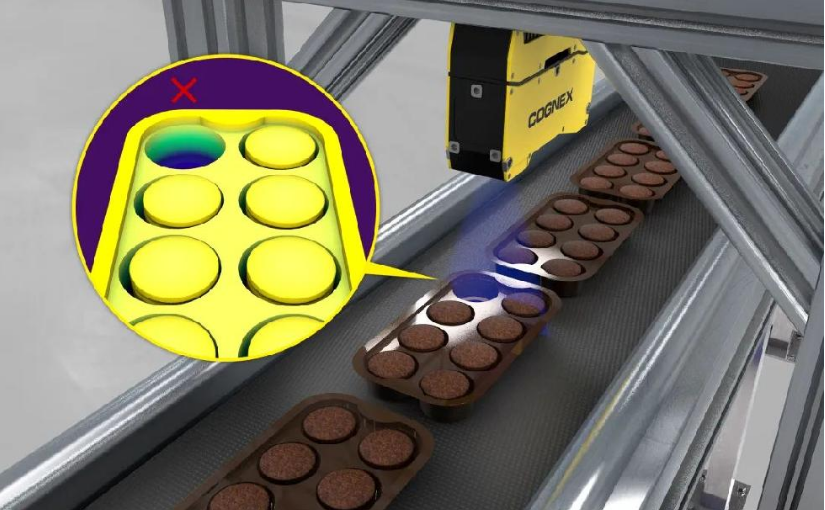

1. Packaging inspection

Determine if there are items in the package and verify the volume of the package.

2. Item location

Check the packing to make sure the quantity and direction are correct. Also check the packaging for defects, such as dents or tears.

Consumer product industry

3D machine vision solutions provide product quality, safety and integrity inspection

The consumer and packaged goods industry requires high throughput, cost efficiency and accuracy to meet its material handling, inspection, labelling and assembly needs. Cognex is uniquely positioned to improve product safety, product quality and productivity for consumer goods (CPG) manufacturers. Cognex provides 3D machine vision solutions for a variety of applications, helping manufacturers maximize gross margins and customer satisfaction by improving product quality.

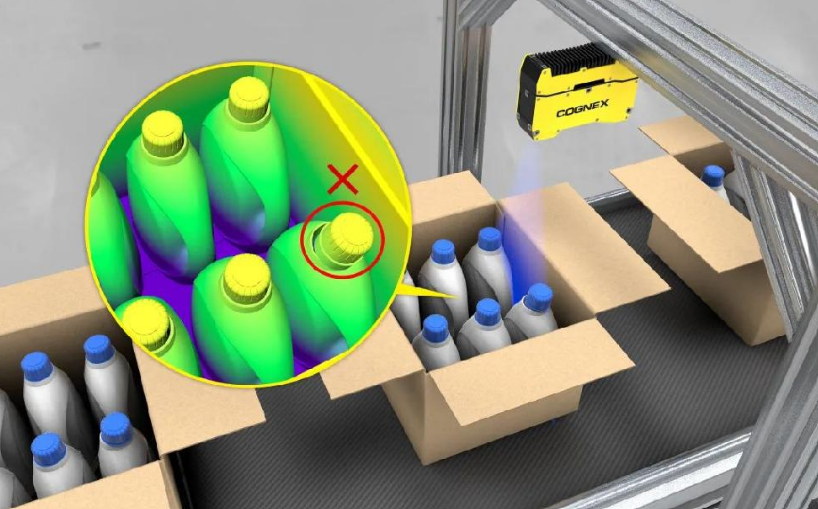

1. Cover detection

Verify the presence and location of the cap by checking the height and tilt.

2. Liquid level detection

Check content height and volume to ensure the correct amount of product in each container.

Logistics industry

Make 3D vision systems more efficient for your operations

As retail distribution, e-commerce and postal delivery continue to grow, they are under increasing pressure to meet customer needs and performance metrics. Successful companies are scaling and optimizing their operations to minimize manual rework and equipment downtime. Cognex 3D machine vision solutions deliver high precision and powerful performance that help improve traceability, increase processing volumes and reduce costs associated with manual rework. In addition, these solutions provide rich real-time performance data and trend insights to help optimize operations.

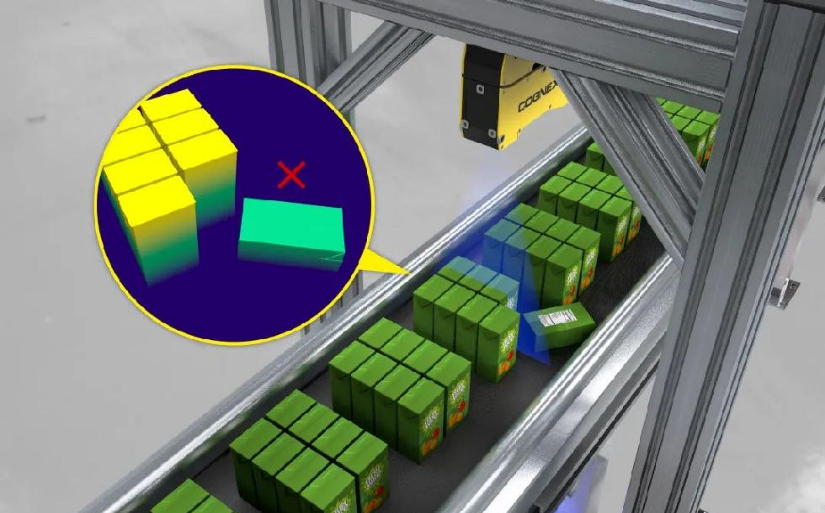

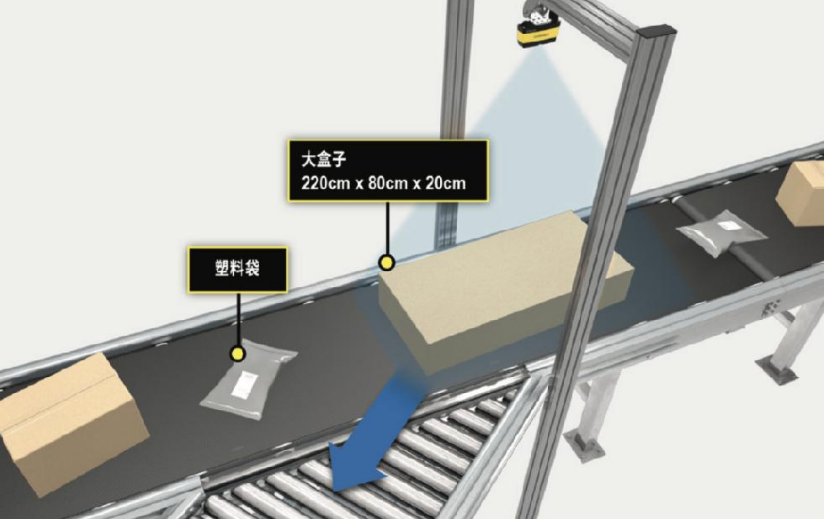

1. Classification of warehousing products

Collect dimensional information, classify incoming goods, and provide item data for appropriate storage.

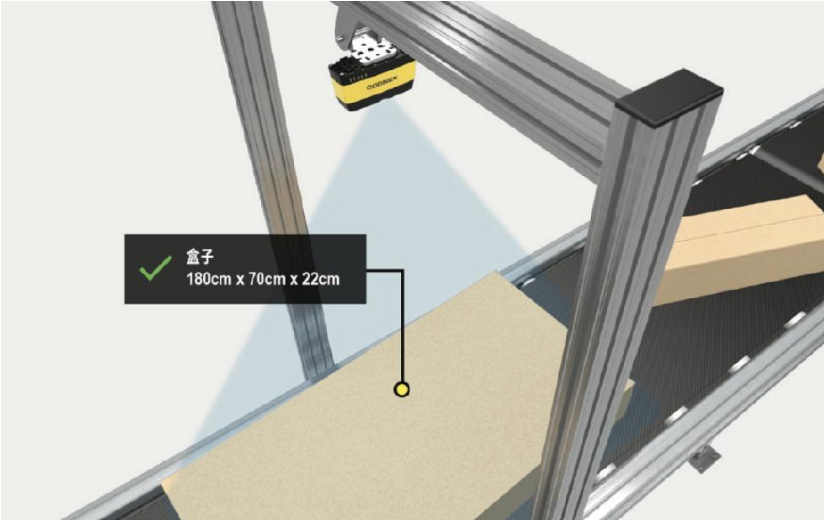

2. Invoice verification

Collect volume and dimension information of incoming products to improve traceability and verify the contents of the manifest.

Disclaimer: This article is from the Internet and is for the purpose of academic communication only. If there is any problem, please contact delete.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu