Equipment Line Control System , abbreviated as BC system. In order to improve production efficiency and product yield, integrating independently functioning upstream and downstream equipment into an automated equipment line has been the major trend in equipment development in recent years. New Xiwang Company has developed the BC system in line with this trend, which is used for fine production and execution during the manufacturing process. Through data statistics and analysis, it enables intelligent equipment management, production management, and control.

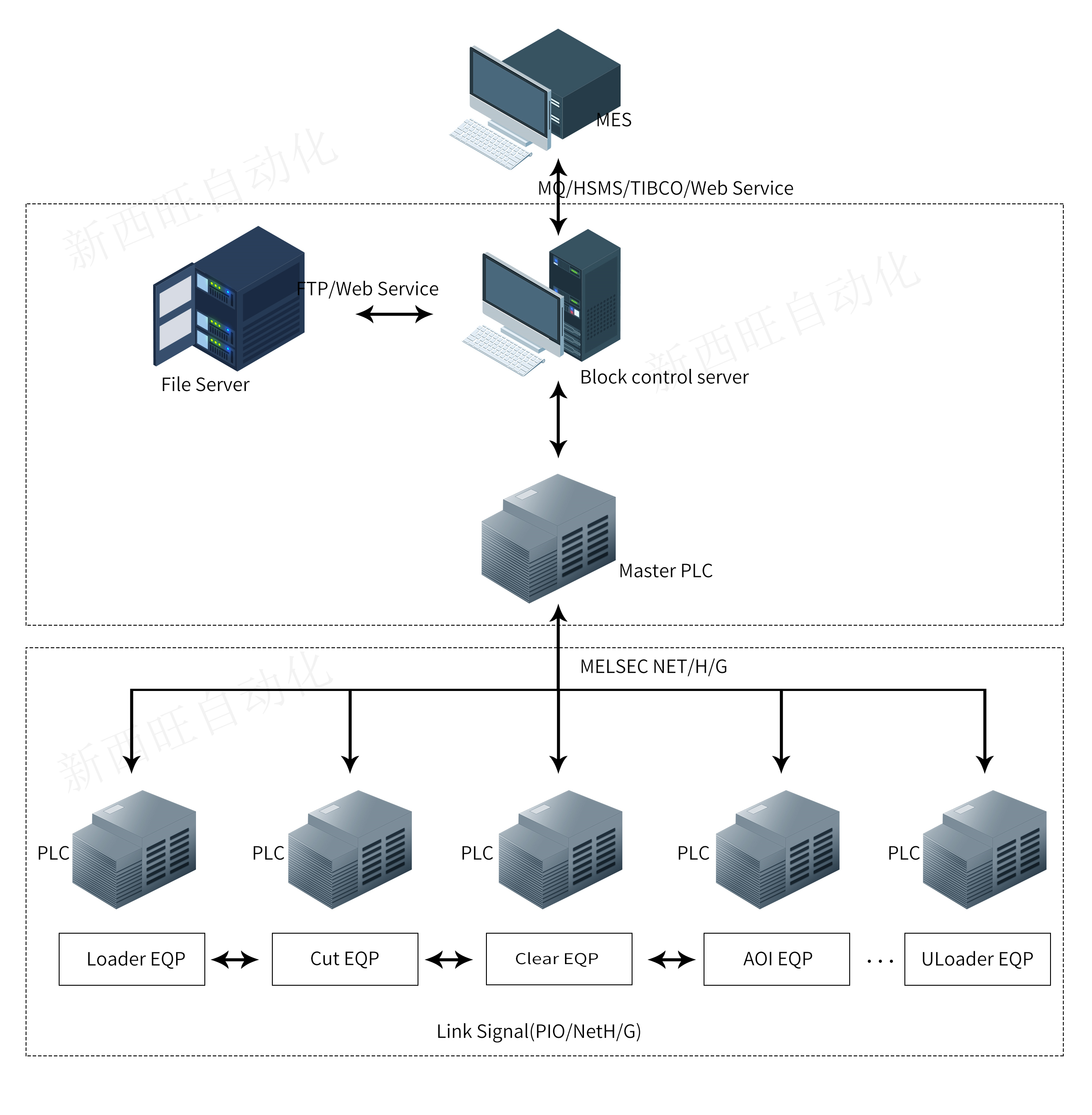

The BC system's system architecture is divided into three layers:

1) Master PLC: The M/PLC is responsible for receiving data from BC and CIM PLCs, acting as a bridge.

2) Block Control Server: It handles communication between M/PLC and MES, sending data to MES, and executing instructions received from MES.

3) Block Control Monitor: It provides system settings for equipment, current operational status, and production data.

What is shown in the above figure is an application case of New Xiwang's BC system, which uploads data from all the equipment in the entire workshop to the BC system's workstation via TCP/IP and then uploads it to the MES system through TIBCO/Ethernet. The uploaded data includes process parameters, machine parameters, material information, AOI parameters, and more.

The Role of New Xiwang's BC System:

1) Integration of Various Equipment: All equipment in the production workshop is connected through communication interfaces.

2) Intelligent Parameter Management: Intelligent parameter management includes process parameter management, equipment parameter monitoring, and real-time data tracking for equipment production. Process parameters include temperature, pressure, equipment parameters include operational setting data and equipment production data. Real-time data tracking for equipment production involves indexing product IDs in the factory database to obtain the corresponding production data for each product.

3) Production Management and Control: Product information tracking allows for traceability of product material batch numbers, corresponding process parameters and machine parameters, temperature, pressure values, and more. Raw material information can be input and controlled, and the BC system automatically acquires the required material information from the MES system. Remaining material can be intuitively viewed, and when the material reaches a warning quantity, feedback is provided to the machine. Prevents errors in material batch numbers and other mismatched production anomalies.

Benefits of using New Xiwang's BC System:

1) Save costs of moving and transferring equipment, improving production efficiency.

2) Control and ensure smooth input and output of all products within the equipment line.

3) Can automatically perform sampling checks within the production line, maintaining high product quality.

4) Automatically collect and report production information in a timely manner and upload it to the MES system for production management and process analysis.

3) After integration with the MES system, it can automatically receive and execute production instructions to achieve efficient and automated production with minimal human intervention.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu