Product introduction

The high-precision intelligent Vision System uses high-precision alignment fitting technology to eliminate lens distortion in the calibration process, and uses hand-eye automatic calibration and joint calibration to calibrate the alignment equipment of multiple cameras and machines in a coordinate system, which can stably and efficiently provide accurate alignment guidance for complex alignment fitting equipment. In the process of application, the motion error of the alignment platform can be evaluated according to the results of translation calibration and rotation calibration in hand-eye calibration. A set of high-precision alignment system with good calibration data can provide guidance alignment efficiently and accurately for equipment in complex environments, and can compensate for fixed errors of equipment. In addition to meeting the alignment accuracy of ±5u, the entire system also needs to add a variety of anti-stay control, including the size control of the product, the accuracy control of the feeding, and the control of whether the alignment is possible (to ensure that the product will not press the fixture). Once these control values are set, they can be easily modified. The exception handling of the whole system is very user-friendly and simple, and after the delivery of the on-site operators are trained, they can immediately start to solve various alarms and anomalies.

Product characteristics

(1) Automatic optical recognition and defect detection technology based on machine vision. Through the automatic optical detection system, when the light intensity is not enough to meet the recognition needs or it is difficult to identify the workpiece in the visible light range, the direction, distance and Angle of the light source are automatically adjusted to provide high contrast image detection, and obtain clear, complete and high-quality workpiece images. And added deep learning capabilities, based on the provided images, can automatically detect tolerable deviations and intolerable defects of the workpiece.

(2) Full-path calibration precision quantification technology. Through the joint work of the laser interferometer and the Vision System, the limitation of the installation space of the automation machine can be overcome, and the quality inspection path and position point can be set without interfering with the regulated mechanism, so that the regulated mechanism can move according to the preset quality inspection path and calibrate the accuracy of each position point of the set execution path. Thus, the accuracy of any section of the whole motion path of the regulated mechanism can be quantified.

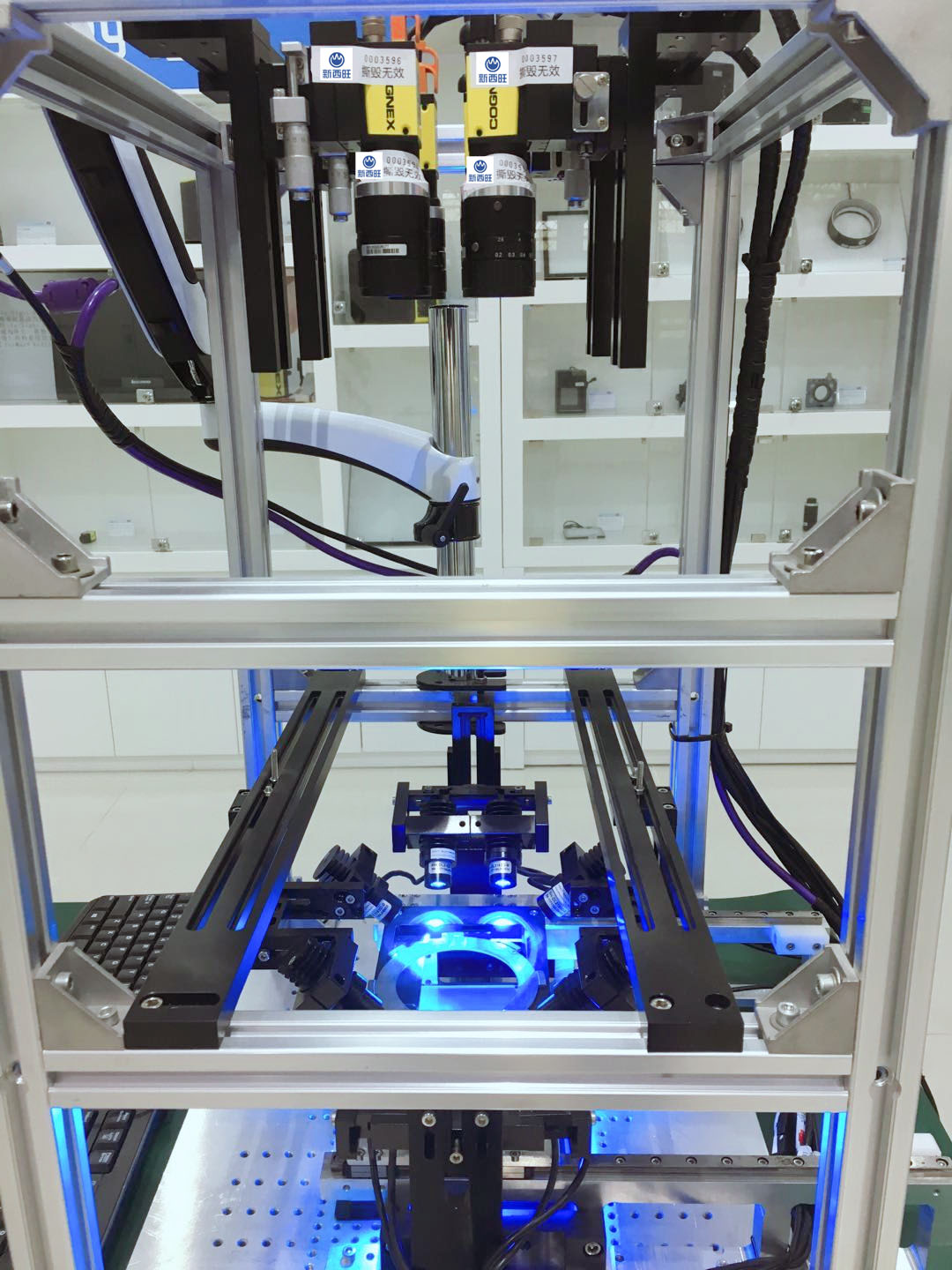

High precision Intelligent Vision System (Figure 1)

Product performance

High precision counterpoint:

Number of virtual cameras: 32 cameras are supported.

Fitting accuracy: ±5μm;

One match rate: 99%;

TT: 500ms (including movement time of the platform);

Automatic optical inspection:

Image data: Simultaneous processing of image data from up to 32 2K pixel industrial cameras;

Phase take: 60 times per second for each camera;

Accuracy: up to sub-pixel;

Detection efficiency: 0.2~0.5s/ piece;

System failure rate: 0%;

NG detection rate: 100%;

Accuracy: 98%.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu