AOI (Automatic Optical Inspection) refers to a detection method that obtains the image of the object under test by optical imaging method, processes and analyzes it with a specific algorithm, and compares it with the standard template image to obtain the defect of the object under test.

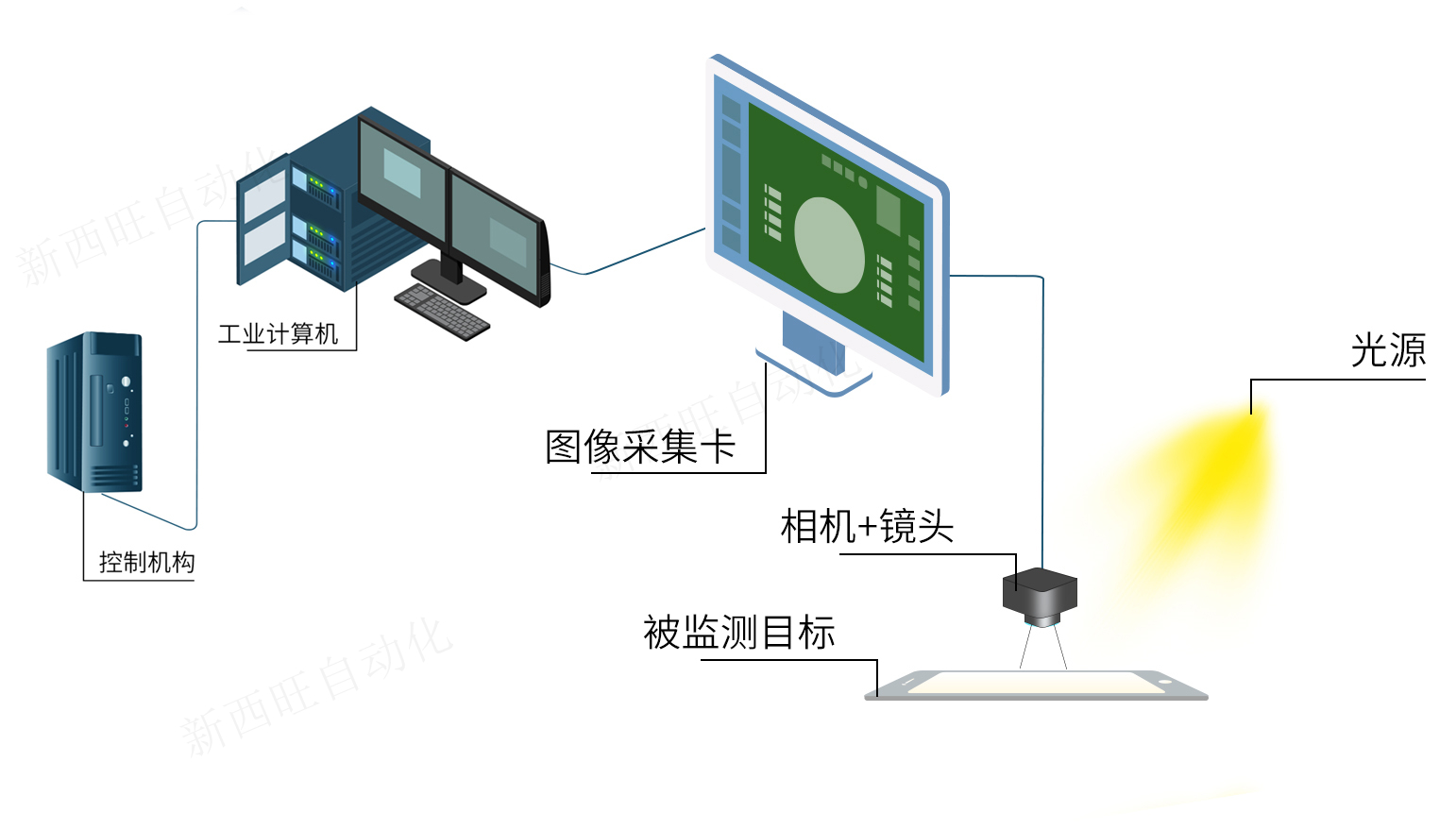

AOI Inspection System (Figure 1)

AOI Vision System is a vision framework system developed by Xinxiwang. The framework is based on Cognex VisionPro dll and developed using C#.NET framework. It supports C# and VB scripts and has rich image processing controls. It is an industrial machine vision platform software, which integrates the hardware control part of the vision system, such as light source control, etc., and also includes the communication of different interfaces, such as RS232 serial ports, Ethernet ports, etc. At the same time, the system is a standalone module that can be used on a variety of devices, supporting a variety of cameras and image capture cards, and can be customized with differentiated vision solutions.

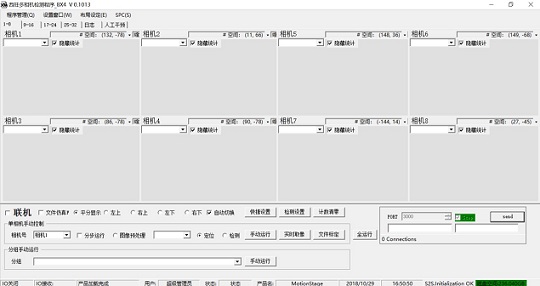

AOI Inspection System (Figure 2)

Xinxiwang AOI System Features:

1) Tool simplification

Users can change the tool module in the visual framework according to the specific needs of the project, and the output parameters of the interface can also be set according to the actual needs. It is easy to use for the operator, greatly shortens the site debugging time of the project, and improves the development efficiency of the project. At the same time, it is also conducive to the later maintenance of the project, and only a simple training of the site operator is required to deal with the anomalies in the actual production process.

2) Function modularization

AOI system framework according to the process, the program is divided into several functional modules, these functional modules only need to change the specific visual tools and module input and output parameters can be re-generated a new program. The modular function of the system framework greatly simplifies the difficulty of the framework, which is more convenient for users to operate, and the divided modules are easy to reuse between different programs, which can reduce the development time and improve the development efficiency.

3) Intelligent processing

Under the characteristics of miniaturization, high-density, rapid assembly and diversified development of products to be tested, the detection information is large and complex, and the detection accuracy and running speed are increasingly required. Xinxiwang AOI inspection system not only meets the requirements of high-speed inspection in complex environments, but also has deep learning function, which can tolerate deviation and unpredictable defects for surface defects, texture and material classification, assembly verification and deformation parts positioning, character reading and distorted printing, etc., with reliable, easy to fit, high-speed and other characteristics.

4) Data visualization

In the actual production process, pictures and data can be stored according to demand. The stored pictures include original pictures, screenshots, NG pictures, etc., and can simulate the actual production process and analyze product data according to the stored pictures. Storable data can be set in the system framework and can be stored according to actual production. The software can record the data of the production link in real time, which is more in line with the requirements of Industry 4.0, so that the production data is real-time, the data is accurate, and the key data is focused. The software also has the function of SPC (Statistics Process Control), which can draw a control chart for analysis of the actual production data, and judge the anomalies of the entire production process and the rules of product data through the control chart. At the same time, the use of statistical data to monitor the production process is conducive to stable production and improve yield.

5) Easy operation

The user-friendly operation interface can set the number of analog cameras according to actual needs, and multiple cameras can run at the same time. After the delivery of the system software, only a simple training of the operator is required to deal with the subsequent production line anomalies and production alarms, without the need for on-site line watchers to have professional visual knowledge, which greatly reduces the later system maintenance costs and processing time. In particular, when the production line is replaced with a new product, it only takes a little time to replace the new product, and there is no need to shut down for a long time.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu