High-precision Alignment Vision System is a high performance, high speed and high precision alignment system developed by our company for the rapid development of the panel industry. In order to improve the competitiveness of its products and the quality of products, the traditional ordinary precision matching system has been unable to meet the ever-changing industry development and accuracy requirements. Therefore, in order to follow up the development of the industry, meet the needs of customers, and improve their competitiveness, Xinxiwang company has invested a lot of research and development efforts to develop a high-precision alignment fitting system that meets today's needs. Once the system is launched, it is highly praised by customers, and can achieve the fitting accuracy that the common alignment software can not achieve.

The biggest advantage of this software is the combination of high-precision alignment movement platform and PLC data conversion module. No matter what kind of motion platform, such as XYθ platform or UVW platform, parameter conversion can be carried out according to the platform parameters and the corresponding XYθ platform, so that the platform alignment parameters can be directly transferred between the PLC and the motion platform, and the accuracy can be achieved without loss. At the same time, the calibration module of the system itself can calibrate multiple cameras and moving platforms to a visual coordinate system, correct the camera distortion error and calibrate the platform translation and rotation, and accurately locate the defects of the platform itself. The most importantly, for this set of mechanism and motion system, the software can provide correction compensation function, through the error compensation parameter setting, can effectively compensate the fixed error of the system.

Xinxiwang high-precision Alignment Vision System Application scenarios:

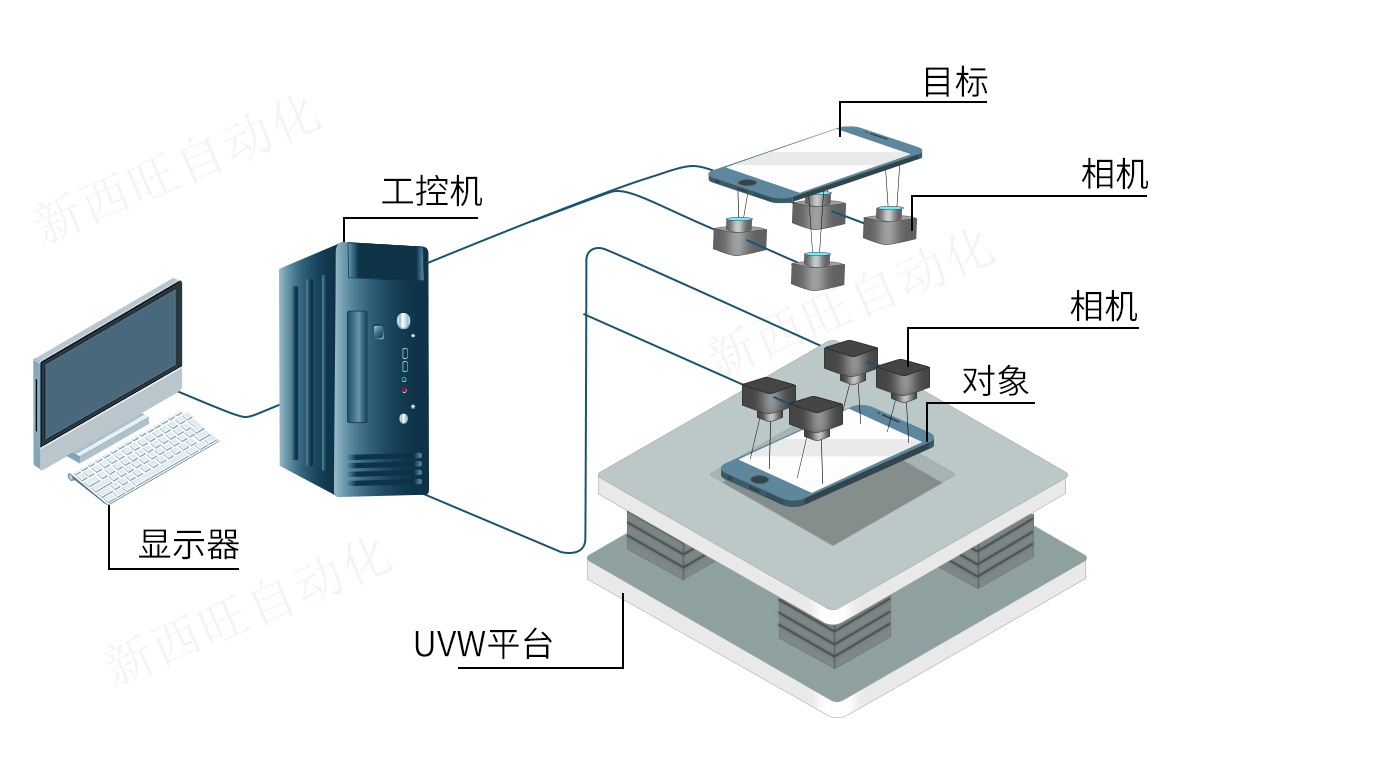

1) An industrial computer with eight physical cameras, two products are aligned, every four cameras take a piece of product, each piece of product takes four corners;

Fitting accuracy: ±3um;

one match rate: 99%;

TT: 500ms (including movement time of the platform)

High-precision Alignment Vision System (Figure 1)

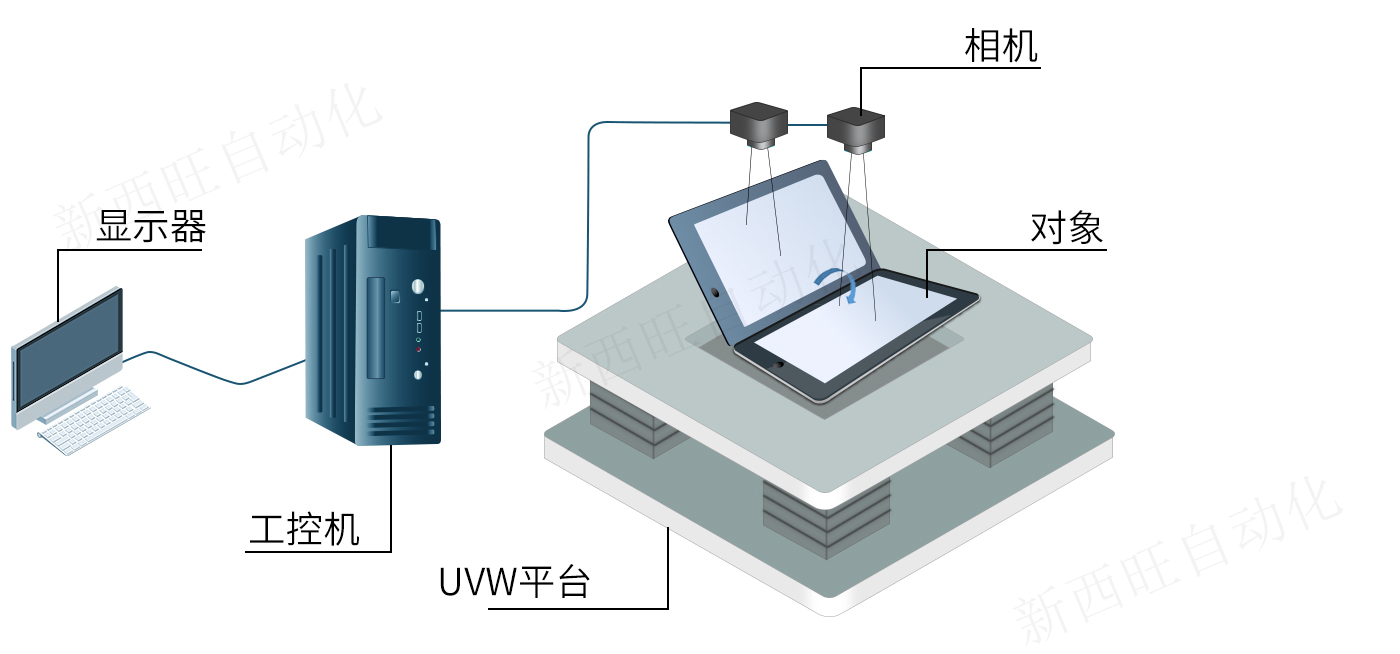

2) An industrial computer with four physical cameras, a piece of product pre-alignment, four cameras respectively shoot the four corners of the product; Or an industrial computer with two physical cameras, a piece of product pre-aligned, the two cameras shot the opposite corner of the product. It can also be based on actual needs, an industrial computer with a physical camera, a piece of product pre-alignment, a camera to shoot the entire product.

alignment accuracy: ±10um;

High-precision Alignment Vision System (Figure 2)

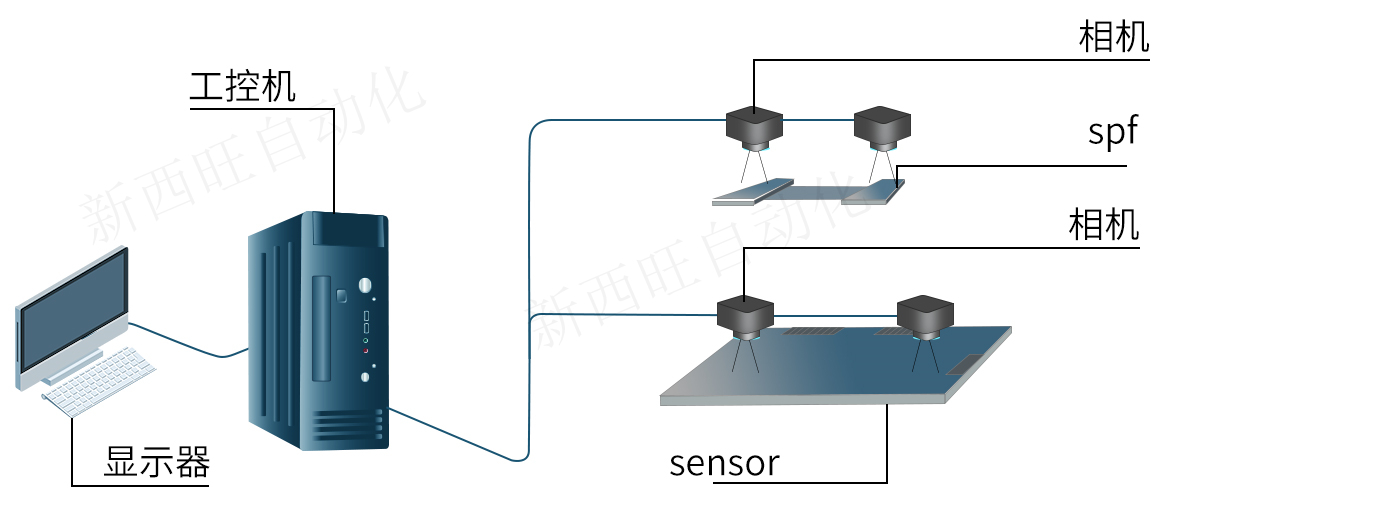

3) An industrial computer with four physical cameras, two product Bonding alignment, there are two Bonding zones, two Bonding zones respectively alignment. Two cameras take a picture of the product, respectively in the Bonding area. The Sensor is located on one motion platform, and the two Bonding zones of the FPC are located on two motion platforms respectively.

Fitting accuracy: +5um;

High-precision Alignment Vision System (Figure 3)

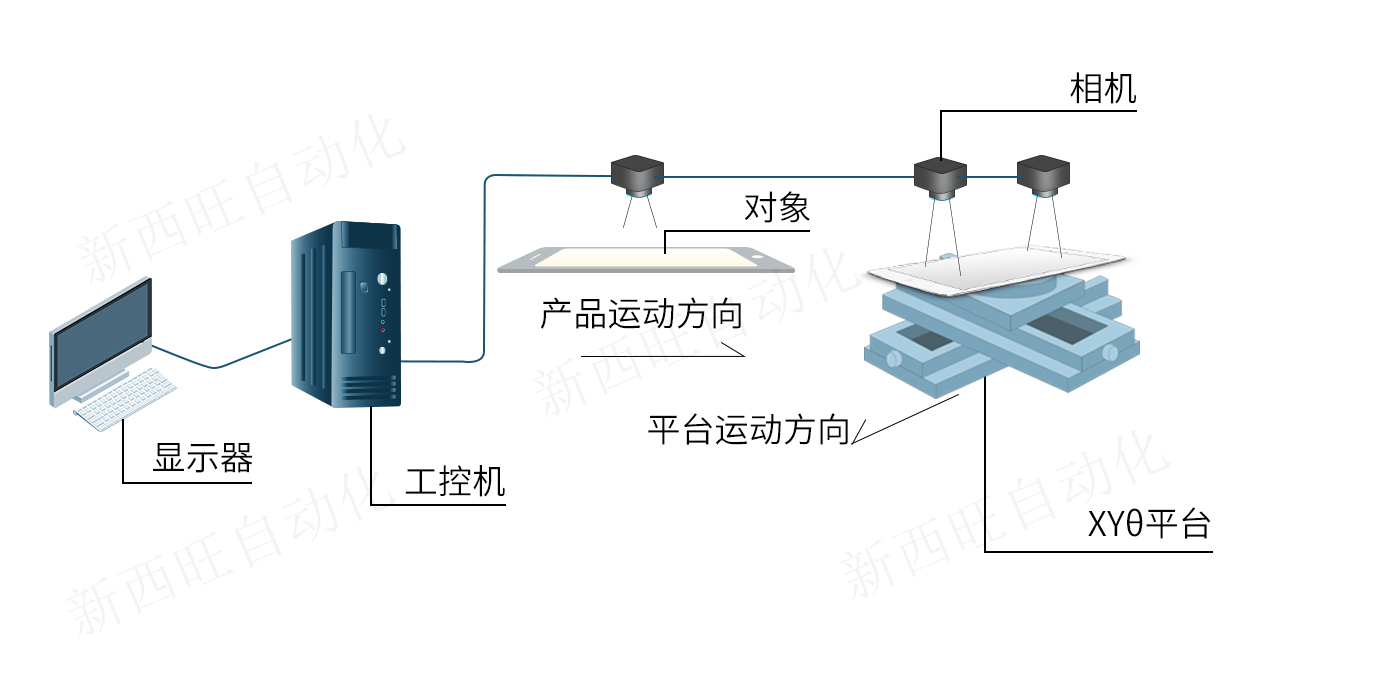

4) An industrial computer with two physical cameras, two products are aligned, the bonding device is flipped. One camera takes one product.

Fitting accuracy: ±10um;

High-precision Alignment Vision System (Figure 4)

5) An industrial computer with 3 physical cameras, two products in position fit. One of the cameras takes a picture of a product, the product moves, the camera is fixed, and the four corners of the product are taken respectively, using one camera to simulate four cameras. The other two cameras take pictures of a product, the product moves, the camera is fixed, and the four corners of the product are taken respectively, and the four cameras are simulated with two cameras.

Fitting accuracy: 50um;

High-precision Alignment Vision System (Figure 5)

High-precision Alignment Vision System features:

1) With automatic correction function

The Xinxiwang High-precision Alignment Vision System includes three calibration methods, nonlinear calibration of the camera, hand-eye calibration of the motion platform and joint calibration of the camera.

The nonlinear correction eliminates the distortion error of the camera and makes the system obtain the image with good consistency.

The hand-eye correction of the moving platform is an automatic correction method, which is convenient to operate and has accurate results, including translation correction and rotation correction of the platform. The translation and rotation errors of the platform can be seen through the hand-eye correction results, which provides a certain data basis for the performance evaluation of the platform. If there is no problem with the platform itself, the results can also reflect whether there are anomalies in the calibration process.

Hand-eye calibration will calibrate the camera and the motion platform into a visual coordinate system, while joint calibration is used when the two products are aligned, and the camera that takes the two products is calibrated in the same visual coordinate system. In this way, the motion platform and all cameras are calibrated in a visual coordinate system.

2) Integrate various sports platforms

The accuracy of the motion platform is the basis of the accuracy of the whole alignment system, if the repetitive motion accuracy of the motion platform itself is not very high, then the accuracy of the visual system cannot be guaranteed. At the same time, the motion platform is also divided into many kinds, and the parameter conversion of the visual system is also one of the important factors affecting the accuracy of the visual system.

The visual system needs XYθ coordinates in the visual coordinate system, while the motion platform, in addition to sending XYθ coordinates directly, is more of a high-precision UVW platform, which is divided into XYY and XXY coordinates. It is necessary to convert the coordinate parameters of the UVW platform and the visual XYθ coordinate parameters. In the Xinxiwang high-precision alignment system, various coordinate parameter conversion methods of motion platform and visual coordinate parameter are integrated. Docking different platforms, only need to modify the parameters of the movement platform can realize the conversion between the two.

3) Support a variety of alignment modes

The Xinxiwang High-precision Alignment Vision System not only supports the pre-alignment of 1 piece of product, but also supports the alignment of 2 pieces of product. The number of cameras in the system can be adjusted according to the requirements of the project, and the physical camera theory that the system can support can be unlimited. The number of simulated cameras that can be supported can be adjusted freely according to the needs.

By adjusting the number of physical cameras and analog cameras, and then modifying the functional modules in the visual frame, it is possible to switch between different alignment modes.

4) Applicable to different institutional forms

The Xinxiwang High-precision Alignment Vision System's high-precision alignment system is applicable to the alignment form of any mechanism, whether it is a film mechanism, Bonding mechanism or STH, HTH bonding mechanism, can use the Xinxiwang High-precision Alignment Vision System to achieve, high-precision alignment system can be said to be unchanged.

In addition to realizing single platform alignment, it can also realize multiple platform alignment at the same time, the most commonly used multi-platform alignment not only meets the accuracy requirements, but also meets customer requirements.

5) Can compensate for fixed offset

The accuracy of the whole product fit is composed of the accuracy of the visual system and the precision of the mechanism system. For a specific mechanism, when the mechanism is generated stable, the fitting effect of the product itself will be affected by the fixed system error of the mechanism and there will be a fixed offset, and this fixed offset cannot be eliminated by adjusting the mechanism. The fixed error of the whole mechanism can only be eliminated by adding a fixed compensation value to the Vision System.

The alignment compensation parameters of the Xinxiwang High-precision Alignment Vision System can be added in different coordinate systems according to the actual needs, so as to eliminate the fixed errors of the mechanism and achieve the fitting products to meet the specified requirements.

6) Achieve high-precision alignment

In the panel fitting industry, not only the alignment fitting mechanism is more complicated, but also the accuracy requirements are more stringent. At present, The Xinxiwang High-precision Alignment Vision System can achieve a lamination accuracy of ±3u. The advanced alignment algorithm developed by the Xinxiwang technical team is able to achieve ±3u fit accuracy in complex mechanisms.

The most important thing is that the accuracy of ±3u can be achieved through a single alignment, and many customers are very satisfied with the Vision System of Xinxiwang.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu