Background

Capsule defect detection is a crucial process in the capsule production industry, providing essential assurance for both capsule manufacturing and consumption. Currently, the main method for capsule inspection in China relies on manual selection, where employees are tasked with sorting capsules. In many cases, the number of workers involved in capsule selection can account for one-third of the total workforce in a capsule factory.

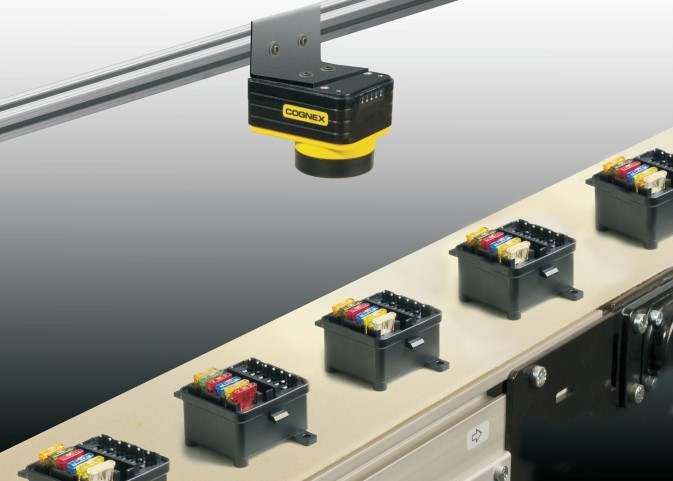

System Overview

In this case, we employ a 30,000 frames per second high-speed industrial camera and a white circular light source. This system automates the detection of capsule color and visual defects (such as underfill, damage, leaking, and misplacement).

Work Results

The detection speed reaches 80,000 capsules per hour, with an accuracy of 0.05mm. The system's accuracy can meet or exceed the customer's expectations, significantly reducing labor costs for the enterprise in this process.

Application Areas

Capsule manufacturing companies, pharmaceutical companies, etc.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu