With the increase of the country's support for the new energy vehicle industry, more and more new energy vehicles have entered the public's field of vision. In addition to traditional car brands, Internet giants have also entered the field of new energy vehicles, and consumers can choose from more car brands and models. More and more families and enterprises are taking new energy vehicles as the first choice for buying and replacing cars.

There is a saying in the rivers and lakes of new energy vehicles:

New energy vehicles, the one who gets the battery wins the world

Power battery technology has become the key to the performance of a new energy vehicle, and many challenging and complex problems are often encountered in the battery production process, which affects the production quality and efficiency. Today, I will introduce you to several smart solutions for battery equipment testing of Cognex products in the automotive assembly process, which can effectively help enterprise factories improve production quality and reduce costs.

1. Battery assembly

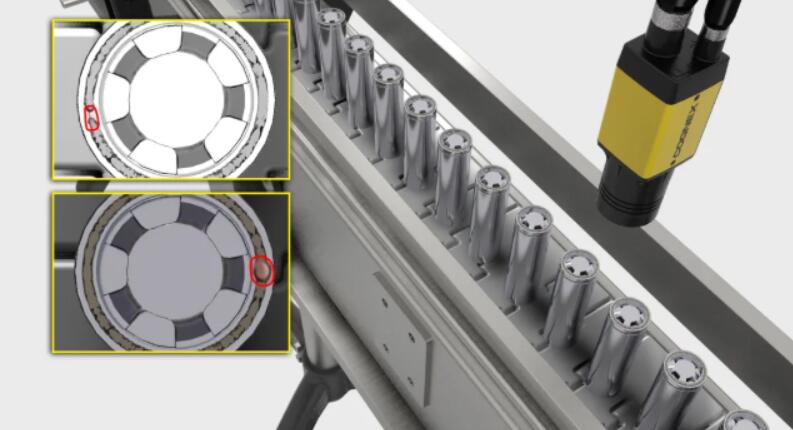

Cap Weld Inspection – Assess the quality of low heat cell welds using classification and defect detection tools

Issue

Poor quality batteries can reduce efficiency, resulting in uneven loads between cells (making battery management more difficult) and shortening the overall life of the battery pack. Once the cells are combined into modules and battery packs, errors in cell manufacturing will be difficult to remedy.

After the electrode and diaphragm are packed into the housing of the cylindrical cell and filled with electrolyte, the housing is sealed with a cap. In order to avoid damage to the delicate electronics in the housing, a low-heat welding method, usually laser welding, is required. This type of welding must be precise to ensure the tightness of the seal around the cap. Before using a battery cell inside a battery module or as a single cell, the resulting weld must be inspected and made sure that it passes the inspection. If any leakage of electrolyte through a defective weld will reduce cell efficiency and may result in a short circuit within the battery.

Solution

Properly evaluating the quality of the cap weld is key to ensuring the functionality and service life of the entire battery. All of these welds can be distinctly different in appearance and may show a wide variety of defects, as well as a wide range of variations that do not affect the performance of the battery. Due to the overlap of appearances, it is almost impossible to distinguish a change in appearance from a significant change in functionality with a traditional vision system.

Cognex deep learning solutions provide defect detection and classification tools that can be trained on a wide range of weld variations. Even if there are changes in the appearance of objects and welds, the system is able to "learn" to accurately classify and distinguish between different types of defects.

2. Battery formation

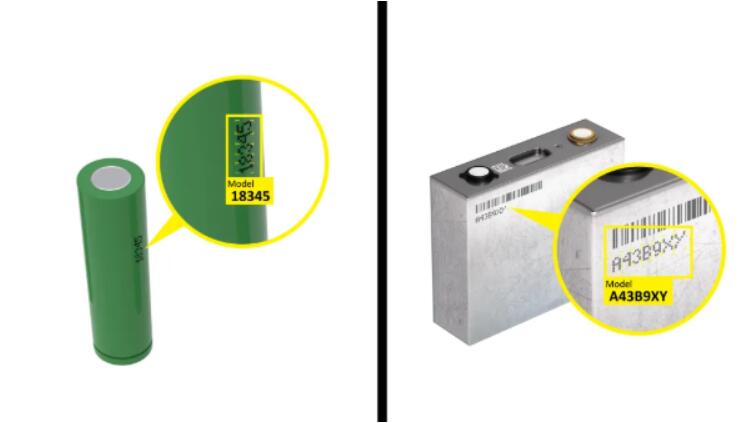

Battery Optical Character Recognition – Deep learning OCR tools read tricky alphanumeric characters on batteries

Issue

Manufacturers must quickly and accurately locate and read alphanumeric codes printed on the bottom of the battery. But in a real-world production environment, especially in the case of character deformation, specular light and glare can make it difficult for machine vision systems to locate and recognize characters.

Solution

Cognex deep learning solutions provide assembly verification and OCR tools to easily locate and read deformed characters. The Assembly Verification Tool locates the Region of Interest (ROI), in this case the top of each cylindrical cell marked with an alphanumeric code. Even when obscured by glare or low contrast, the OCR tool's pre-trained full-font feature recognizes characters.

To train the software, engineers define a region of interest on an image that contains a representative set of code characters. During training and validation, the technician only needs to re-label the missing characters until the software model correctly recognizes all the characters. This deep learning-based OCR method reduces excessive labeling, which saves time required during training and development and ensures accurate reads.

3. Modules and battery packs (M&P).

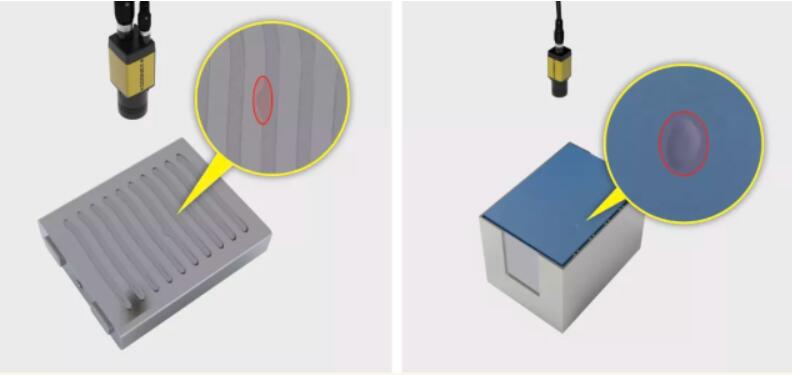

Thermal Interface Material (TIM) Inspection – Use deep learning solutions to ensure proper use of thermal interface materials

Issue

Batteries generate a lot of heat, which must be removed to prevent battery damage or premature degradation. Thermal interface materials (TIMs) are used to conduct heat away from the battery. Many thermal interface materials also perform an equally important electrical insulating function. Thermal interface materials must be applied precisely and the substrates should be in close contact with each other. A wide variety of defects, including air bubbles, poor adhesion, and inclusions, can lead to reduced thermal and electrical insulation. Vision inspection systems must identify a variety of defects that may be present in installation and application, often involving materials with poor color contrast. After the battery assembly is moved to the next step, the thermal interface material is permanently hidden and cannot be further inspected. Errors that occur at this stage can lead to problems downstream of the production line that are difficult to diagnose.

Solution

While rule-based machine vision can accurately detect expected issues such as beads, gaps, mounting widths, and other common features, Cognex deep learning solutions can learn to detect a wider range of mounting issues in various types of thermal interface materials. If the battery fails in later use, failure modes can be identified based on specific images of the stored thermal interface material, and you can further improve the deep learning training model to detect these new errors.

Disclaimer: Some of the content and pictures in this article are from the Internet, which is only for the purpose of academic communication. If there is anything wrong, please contact us to delete it.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu