As a beginner in the machine vision industry, I don't know how to choose light sources and lenses, so I can't help but take a look at the following selection process of machine vision light sources and industrial lenses.

1. The process of selecting a machine vision light source:

1) Understand the project requirements and clarify the objectives to be detected or measured.

2) Analyze the difference between the target and the background, and find out the optical phenomenon with the largest imaging difference between the two.

3) According to the coordination relationship between the light source and the target, the luminous type and color of the light source are preliminarily determined.

4) Take the actual light source to test to determine the lighting method that meets the requirements.

5) According to the specific situation, determine the products applicable to customers.

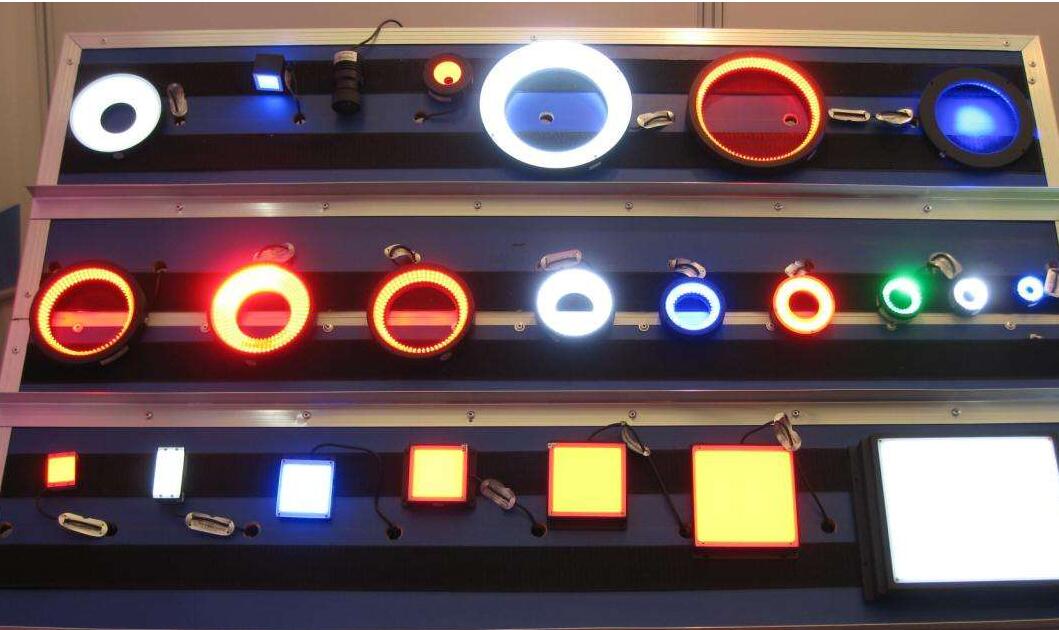

Introduction to the common types of machine vision light sources

1) Ring light source: provide different illumination angles and different color combinations, which can highlight the three-dimensional information of the object; High-density LED array, high brightness; A variety of compact designs save installation space; Solve the problem of diagonal illumination shadows; Optional diffuser light guide to spread the light evenly. Application fields: PCB substrate inspection, IC component inspection, microscope illumination, liquid crystal correction, plastic container inspection, integrated circuit printing inspection.

2) Backlight: High-density LED array surface provides high-intensity backlight illumination, which can highlight the outline characteristics of the object, especially suitable as a stage for microscopes. The red and white dual-purpose backlight and the red and blue multi-purpose backlight can be blended in different colors to meet the multi-color requirements of different measured objects. Applications: Measurement of the size of mechanical parts, appearance detection of electronic components and ICs, film stain detection, transparent object scratch detection, etc.

3) Bar light source: it is the preferred light source for large square structure test objects; Colors can be matched according to needs and can be freely combined; The irradiation angle and installation can be adjusted at will. Applications: metal surface inspection, image scanning, surface crack detection, LCD panel inspection, etc.

Coaxial light source: It can eliminate shadows caused by uneven surfaces, thereby reducing interference; Some of them are designed with beam splitters to reduce light loss, improve imaging clarity, and evenly illuminate the surface of objects. Applications: The series of light sources* is suitable for scratch detection on the surface of objects with high reflectivity, such as metal, glass, film, wafer, etc., damage detection of chips and silicon wafers, Mark point positioning, and packaging barcode identification.

4) Linear light source: ultra-high brightness, using cylindrical lens to concentrate light, suitable for various assembly line continuous detection occasions. Applications: Array camera lighting, AOI.

5) Point light source: high-power LED, small size, high luminous intensity; Alternative to fiber halogen lamps, especially suitable as coaxial light sources for lenses, etc.; Efficient heat dissipation device greatly improves the service life of the light source. Applications: Suitable for telecentric lenses, used for chip detection, mark point positioning, wafer and liquid crystal glass base correction.

2. Selection process of industrial lens:

In the machine vision system, the main role of the industrial lens is to image the workpiece to the camera sensor chip, so the selection of the lens will directly affect the overall performance of the machine vision system.

1) First, determine the application requirements (field of view, accuracy, installation height, etc.);

2) Calculate the key optical performance parameters according to the application requirements. For example, the focal length is calculated from the field of view, camera, sensor size, and working distance:

Field of view (horizontal) Working distance ≈Chip (horizontal) focal length

3) Resolution matching: In practical applications, it should be noted that the resolution of the lens is not lower than that of the camera;

4) Depth of field requirements: For projects that require depth of field, use a small aperture as much as possible.

Due to the many influencing factors of depth of field and the subjective judgment criteria, the specific calculation of depth of field needs to be combined with the actual use conditions.

5) Pay attention to the cooperation with the light source and choose the appropriate lens;

6) Pay attention to the installation space of the use environment.

Precautions when selecting industrial lenses:

1) Focus ring. The imaging effect of the focus ring varies greatly from state to state.

2) The mechanical interface that connects the lens to the camera. Common interfaces in the industry have been formed into general specifications, such as C-port, CS-port, F-port, and K-port.

3)* Large compatible camera chip size. *Large compatible camera sensor size refers to the range of large and clear images that the lens can support. When actually selecting a camera and lens, it is important to note that the size of the compatible sensor of the selected lens should be greater than or equal to the size of the selected camera sensor.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu