With the development of the medical industry, the infusion bag can store the liquid medicine and isolate it from the outside world, prevent bacterial infection, and realize a variety of clinical infusion methods of nutrient solution. However, when the production workshop is in the assembly line, it is necessary to check whether the infusion bag has bubbles, cracks, burrs and other defects online. However, manual detection is labor-intensive; Normal human eyes will observe moving objects for about 30 minutes continuously, which can cause discomfort such as dizziness and eye swelling. Intermittent work cannot guarantee the factory pass rate of products; There are many types of defects in infusion bags, some of which are very small, which cannot be accurately judged by the human eye, with large errors, many opportunities for errors, and the quality of testing cannot be guaranteed. In order to improve productivity and ensure the quality of infusion bag production, Xinxiwang editor recommends that you choose a machine vision system to detect, and the following is a machine vision inspection solution for infusion bags.

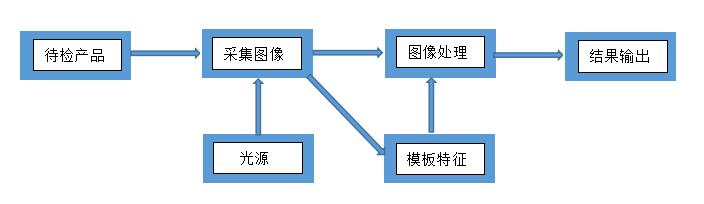

【Principle of Machine Vision Inspection】

The machine vision inspection system converts the acquired target into an image signal through machine vision products (CMOS and CCD), transmits it to a dedicated image processing system, and converts it into a digital signal according to information such as pixel distribution and brightness. The image system performs various calculations on these signals to extract the characteristics of the target, and then controls the on-site equipment action according to the results of the discrimination, and performs visual inspection, dimensional measurement, defect detection, and system positioning.

【Advantages of Machine Vision System】

1. Convenient operation, simple operation, just click "Start", "Stop" to complete all operations.

2. High stability, can work continuously in extreme temperature and plant environment.

3. When defects are found in 100% surface detection, an alarm can be issued according to the setting to prompt timely repair to avoid the generation of a large number of defective products.

4. Complete surface quality information: The surface defect image of the material is saved by the computer, and each roll of the product has complete defect image/location and quantity information, and the edge of the product format can be automatically labeled as needed.

5. The high-precision detection scheme can detect 100% defects above 0.02 square millimeters to meet the customer's continuously improving product quality requirements.

【Machine Vision Inspection Results】

It can be seen that the infusion bag defect detection through machine vision has high stability and can work continuously in the complex production workshop, improve productivity and ensure the production quality of the infusion bag.

Disclaimer: The pictures in this article are from the Internet and are only for the purpose of academic communication. If there is anything wrong, please contact us to delete it.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu