In the medical industry, disposable syringes are a common medical device. Because it can effectively avoid cross-infection, it has been widely promoted and applied. As shown in Figure 1, a disposable syringe mainly consists of a syringe and a needle tube. Syringe character defects have a great impact on the appearance and use of the syringe. The main cause of syringe character defects is quality problems such as missing characters and defects during the printing process.

For mass production, checking character defects by visual inspection or touch can easily cause visual fatigue or even scratch your fingers with the tip of a needle. On the other hand, manual inspection is inefficient, easy to miss, and difficult to ensure product quality, which seriously affects the production efficiency of disposable syringes.

1. Difficulties and purposes of detection

The syringe barrel is a transparent cylinder and cannot be completely detected at one time when detecting characters. When using a line scan camera for image collection, due to the transparency of the syringe, the characters on both sides of the syringe will interfere with each other's detection. As shown in Figure 1, the colors of the characters above the syringe in this experiment are black and red, and compatibility should be considered during the production process.

This case aims to use machine vision inspection to eliminate reflections and character interference on the opposite surface of the syringe, so as to detect the integrity of the syringe characters.

2. Visual inspection hardware system

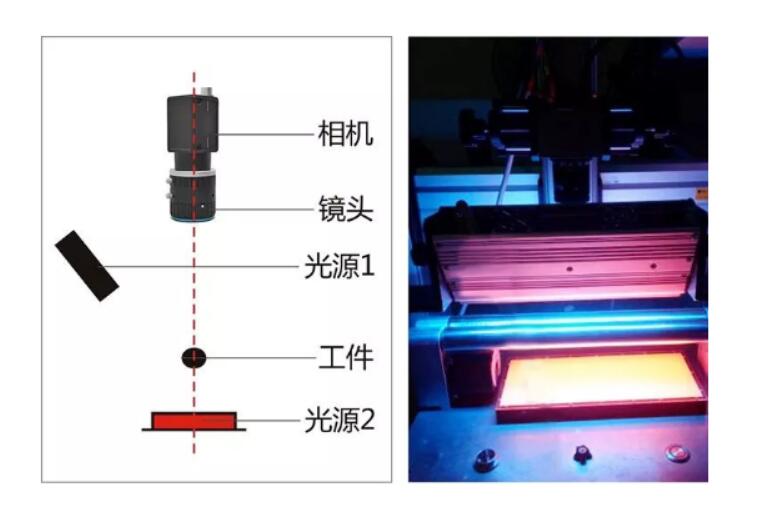

The experimental environment is a self-built simulated field environment. As shown in Figure 2, this experiment used a line scan camera that is highly used in the printing industry. It can scan the syringe continuously and at a uniform speed during the production process of the syringe, thereby achieving uniform detection of the entire surface of the syringe. This lens uses a high-definition 10-megapixel fixed-focus lens. The resolution of the full field of view can reach 140lp/mm, ensuring the clarity of the image. Since the color of the syringe characters is divided into black and red, we need to use the same lighting method to achieve compatibility.

In the experiment, we used a high-brightness linear light source to slant from the top of the workpiece. This lighting method enables clear contrast between the characters and the background and satisfies the best compatibility. In addition, since the shape of the needle barrel is cylindrical, if only one headlight is used, the interference of the characters on the opposite side cannot be eliminated, so a parallel backlight needs to be added to eliminate the interference.

3. Obtain images

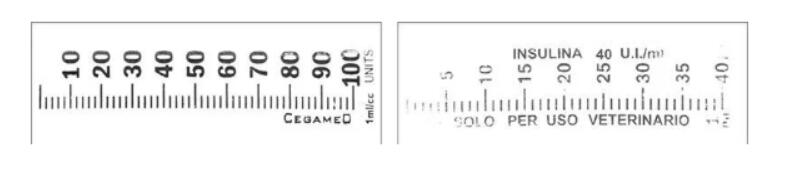

Through the reasonable combination of the above lighting methods and machine vision hardware, not only clear images are obtained, but also the compatibility of the collected images is well achieved. The effect is as follows:

4. Software processing effect

When detecting character defects, due to the large differences in the shapes of different characters and the lack of fixed shapes, it is difficult for ordinary algorithms to effectively inspect their integrity.

Machine vision software is rich in functions, including image, enhancement, positioning, measurement, detection, identification, communication, control and other functions. Combined with the algorithm library (SDK) in the visual development kit, users can also develop applications flexibly and directionally according to their own needs.

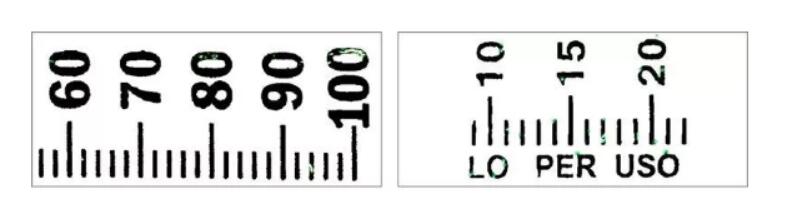

As shown in Figure 6 and Figure 7, use the image enhancement functions such as binarization, rotation and translation in the machine vision software to adjust the positions of the image to be detected and the template, and then use the variable model detection tool to compare the character image to be detected with the standard template. Compare and calculate the size and position of the missing characters. Even when the character accuracy is extremely low, the intelligent vision software SCI can accurately locate the character defect location and size.

5. Case summary

This article uses a syringe as the experimental object of transparent objects, uses machine vision hardware , and combines intelligent vision software to overcome the difficulty of detecting transparent objects and achieve detection compatibility of transparent objects in the actual production process. If you need to know more machine vision inspection cases and solutions, you can call the hotline: 028-62705808 Ms. Wu

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu