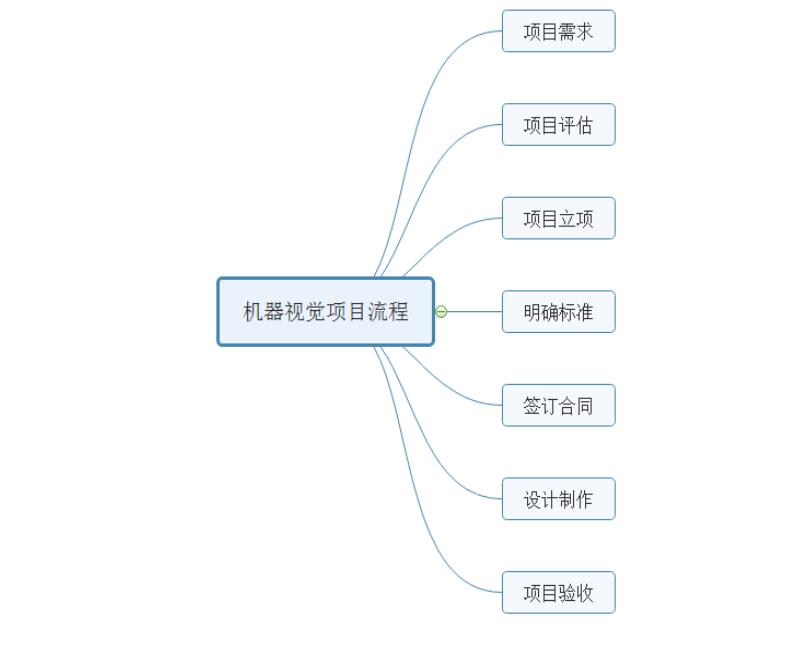

With the widespread application of machine vision , more and more companies are beginning to use machine vision system solutions . In order to smoothly introduce and implement vision system solutions, Xin Xiwang briefly introduces the entire process of the machine vision inspection system from early product inspection and evaluation to vision system solution design.

1. Preliminary evaluation of the project

a. Inform us of the approximate requirements for your visual project via phone or online customer service. The company will have professional project engineering engineers conduct preliminary communication with you to understand your needs in detail.

b. You are required to provide testing samples (several OK products and various NG products) and the on-site environment. If you are not doing complete machine testing equipment, you also need to provide installation space for visual equipment and peripheral IO communication. If necessary, project engineers can also come to your company for on-site assessment.

c. Based on the samples provided, the project engineer will conduct a preliminary technical evaluation in the company, and the test results will generally be given within 2 to 3 working days after receiving the samples.

d. The project engineer will provide you with professional advice based on the test results. Provide you with suitable vision products (including industrial cameras, lenses, light sources, computers, machine vision system software selection, etc.), and then provide you with preliminary plans and project cost estimates after the test results are available.

e. If you have any questions about the plan, you can contact the project engineer at any time. The project engineer will answer your questions and improve the plan, and try its best to meet your needs.

2. Project establishment

After the project is initially evaluated and both parties confirm the feasibility of the project plan, the project engineer will then establish a new project process to proceed.

3. Clarification of testing standards

You need to collect OK products and limited NG products (that is, the types of NG products that can be detected in the preliminary test), and a certain amount is required. The project engineer will test the samples you provide and confirm the detailed testing standards with you.

4. Confirmation of other matters

After clarifying the testing standards, the project engineer will further confirm with you that the testing equipment meets the installation site, mechanical and electrical requirements; if your company has special requirements for the use of equipment, please submit them in time so that we can evaluate and design.

5. Production of overall plan, detailed quotation, and contract production

Based on the above confirmation, the project engineer produces a detailed overall plan, which includes complete machine diagrams, visual system configuration, inspection standards, software functions, etc.

Machine vision system solution design and production process

After signing the contract and confirming all aspects of finance, further design and production of system equipment will begin. Generally, it will go through the following stages:

1. Provide relevant samples

It is necessary to provide different levels of good and defective product samples, product sample appearance dimensions and design product carriers. If you need to use a special vehicle, please provide the relevant dimensions of the special vehicle for our design use.

2. Confirmation of the overall equipment layout diagram and electrical control action flow

A few working days after receiving the relevant samples provided by you, we will provide the overall equipment layout diagram and electrical control action process to the person in charge of your company for confirmation. If you have any questions, you can communicate with the company's technical engineers, who will solve them as soon as possible. your question.

3. Machine parts drawing design

After the overall machine layout is confirmed, the next step is to design the mechanical parts.

4. Selection of mechanical and electrical standard parts

After the overall machine layout diagram and electronic control action flow are confirmed, the next step is to complete the selection of mechanical and electrical standard parts.

5. Material procurement and parts processing

Material procurement, all channels are carried out according to formal procedures, product quality is strictly guaranteed, and material procurement and parts processing are completed.

6.Visual and electronic control software design

In terms of visual software design: the software’s positioning is accurate, the algorithm is stable and reliable, the interface is friendly, beautiful, simple to operate, and parameter adjustment is convenient. When the software reaches the detection capability, the detection time is minimized and the adjustment is minimized. Small.

7. Complete machine assembly and trial operation

After each part has passed the inspection, it is transported to the assembly site for assembly. The entire assembly process is carried out mechanically and electrically in strict accordance with the requirements of the drawings, and no detail is ignored. After the assembly is completed, run the machine empty and run in the moving parts.

8. OK/NG sample testing

After the whole machine runs dry for a period of time, test the OK/NG samples and test the electronic control action of the equipment. Will the mechanism cause secondary damage to the product? Is the software detection accurate and stable? When the above tests meet the contract requirements, pre-acceptance before shipment can be carried out.

The last step is the shipment of machine vision equipment, on-site mechanical installation, imaging effect debugging, visual inspection software debugging, electrical debugging, maintenance personnel training and production, and provision of equipment maintenance instructions. Such a systematic visual inspection solution process That’s it, I hope this article was helpful to you.

If you need to know more about machine vision products and machine vision inspection solutions , you can call the service hotline: 18215640190

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu