Test requirements:

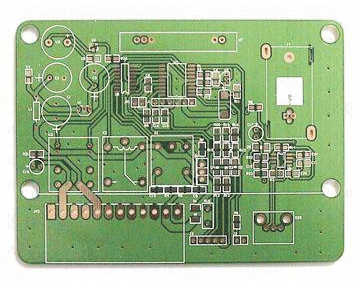

Detect the position of the positioning hole on the PCB board and send it to the moving mechanism for matching.

Detection accuracy:

The positioning hole precision is 0.015mm.

The positioning line accuracy is 0.025mm.

Project introduction:

1. Image acquisition module: Light source is lit under the control of external trigger signal, and the camera acquires and displays images.

2. Setting module: The professional visual positioning tool Patmax is used for positioning, and the detection accuracy is 1/40pix.

3. Image processing module: The image can be obtained by lighting, and the specified area of the image can be digitized, which is conducive to extracting the feature points of the workpiece to be tested.

4. Control module: can communicate with a variety of different types of PLC, support a variety of different communication protocols such as RS232, RS485, IP-LINK, etc. The detected information can be sent to the next level for processing.

Application field:

PCB manufacturing, mobile phone, tablet computer manufacturing and other electronic manufacturing industries.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu