1.1Background Introduction

In the panel assembly industry, precise alignment and lamination on various devices are common, such as film laminators, binding machines, and full assembly machines. As production processes improve and product generations change rapidly, the requirements for product production parameters become more stringent. Ordinary visual alignment systems are no longer sufficient, and high-precision alignment and lamination systems have emerged. These systems can precisely guide the alignment of FPC Bonding Sensors, sensors, CG (Cover Glass) lamination, protective film/heat dissipation film, and CG lamination. They can achieve a one-time alignment accuracy of ±5 micrometers, enhancing product quality and competitiveness for businesses.

1.2System Performance

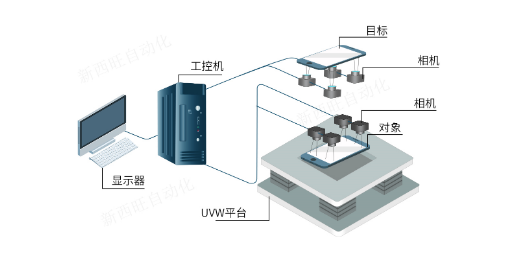

The high-precision alignment system eliminates lens distortion during calibration. It employs hand-eye automatic calibration and joint calibration to calibrate the alignment equipment of multiple cameras and machines in a unified coordinate system. This system can provide precise alignment guidance for complex alignment and lamination equipment in a stable and efficient manner. During application, the translation and rotation calibration results from the hand-eye calibration can be used to evaluate the motion error of the alignment platform. A well-calibrated high-precision alignment system can efficiently and accurately guide equipment in complex environments and compensate for fixed errors in equipment.

Apart from achieving an alignment accuracy of ±5 micrometers, the most challenging aspect of the entire system is the need to add various fail-safe controls. This includes control of product dimensions, precision control during loading, and control of whether alignment is possible (ensuring that products do not press onto fixtures). Once these control values are set, they can be easily modified. The entire system has a very user-friendly and straightforward exception handling process. After training the on-site operators upon delivery, they can immediately handle and resolve various alarms and exceptions.

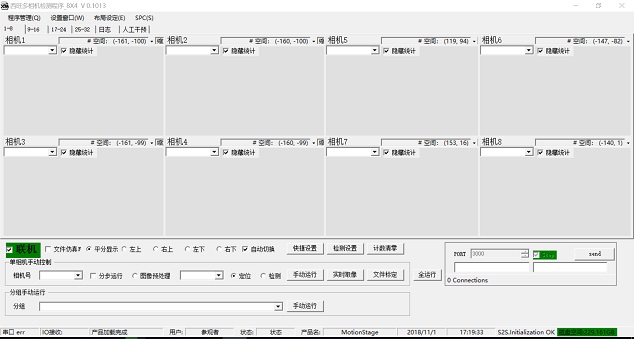

Software Interface

One-time alignment accuracy: ±5um

One-time alignment accuracy: 99.99%

Number of CCD cameras in the system: 8

Application equipment: Various alignment and lamination devices

1.3Work Results

This system can work long-term, stably, and accurately in complex alignment and lamination equipment. It can ensure alignment precision and achieve a one-time successful alignment, significantly reducing alignment time. It meets customer requirements and enhances the accuracy of lamination and production stability.

1.4Application Field

Panel industry

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu