Background

The factory needs to implement a detailed and accurate work plan for production processes, product tracking and control, quality management, process management, real-time and accurate data collection of production parameters, and monitoring of production anomalies for each product and incoming material quality. An automatic accounting system needs to be added within the machinery.

Labor costs are continuously increasing, and reliability is low. To meet the production speed of the machines, a substantial amount of manual labor is required.

Ensuring product traceability is essential.

There are more than 40 production lines in the entire manufacturing workshop, each line consisting of 8 automated machine types and multiple semi-automated machine types. There is an urgent need to replace the inefficient and error-prone manual accounting method with an automatic accounting system, in order to adapt to the factory's production processes.

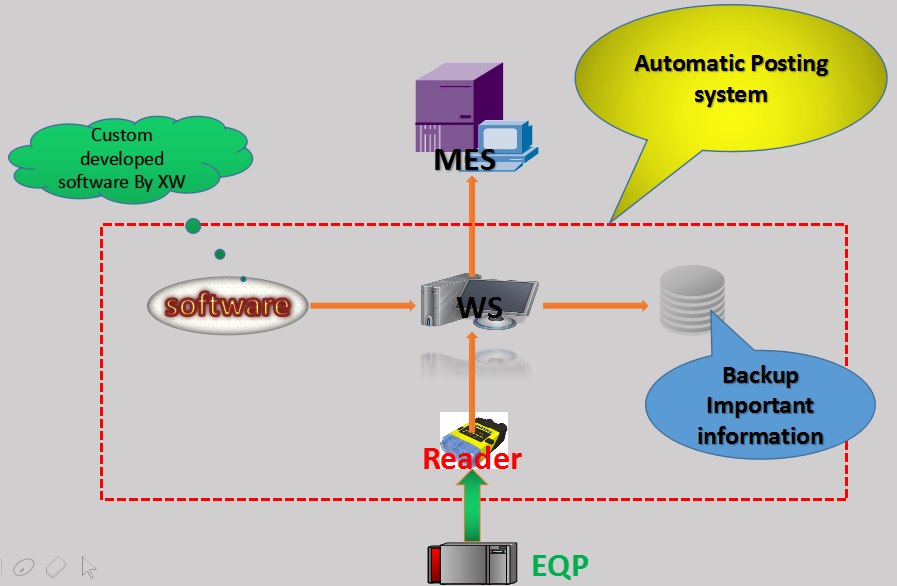

Solution

Collect information from the Barcode readers.

Organize the data as per customer-specified formatting requirements and send it to the factory MES system.

Ensure accurate linking between FOP workstation sensors and FPC Barcode information.

Ensure accurate linking of FPC and Shield Barcode information between STS1 and STS2 workstations. The linking method is different from that of the FOP workstation and requires data caching and interaction with machine information to prevent data disorder.

Control of the production process and error prevention function to promptly identify product rework anomalies and missed workstation production anomalies, meeting the factory's requirements for production and process control.

Achieve monitoring of incoming materials and production analysis by storing real-time product information and related information files.

Read Barcode Type Features:

Barcode Parameters | Barcode Medium | FPC | Sensor1

| Shield |

Barcode Type | Data Matrix | Data Matrix | Data Matrix Code | |

Barcode Process | Dot Matrix Inkjet Printing | Laser Etching | Grid Inkjet Printing | |

Barcode Size | 3mm*3mm | 0.7mm*1.5mm | 8mm*8mm | |

Barcode Color | Black | Black | Black | |

Background Color | White | White | Blue Transparent Film |

Single System Structure:

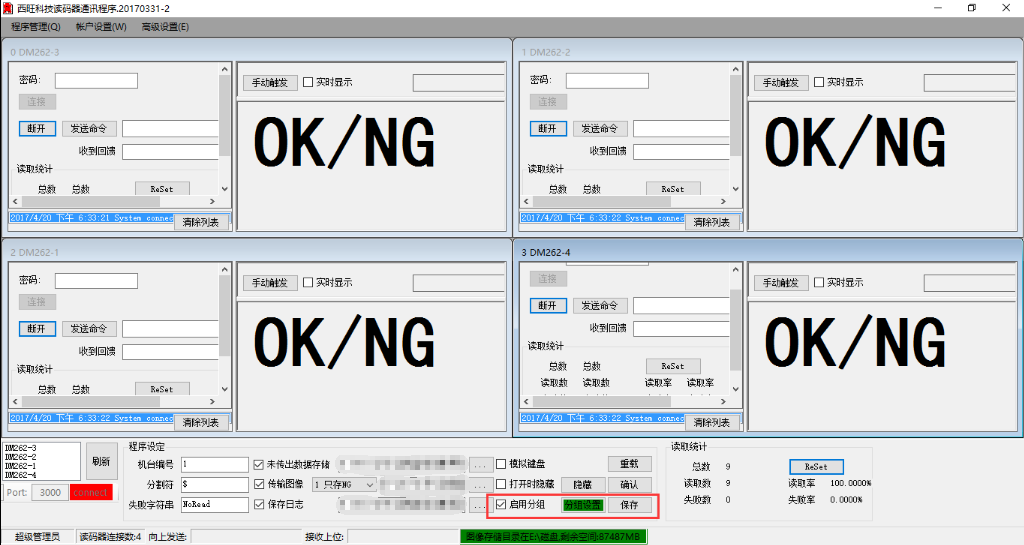

Software Interface:

Product Images:

Work Effects:

This system is applied in multiple automated production factories and has achieved a 99.99% success rate in reading. In practical applications, Cognex's series of decoders are compatible with reading QR codes of different sizes. They provide rapid automatic focusing and quick automatic light source switching to overcome issues like warped incoming materials and significant position variations. Powerful decoding algorithms address problems related to the unstable quality of QR code processes. Throughout the usage process, the reading speed of the decoder ranges from 30ms to 500ms. The convenience and stability of the automatic accounting system have received high recognition from customers and saved a significant amount of labor costs.

Application Fields:

Electronics, Panel Manufacturing, Automotive, Packaging, Food Industry.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu