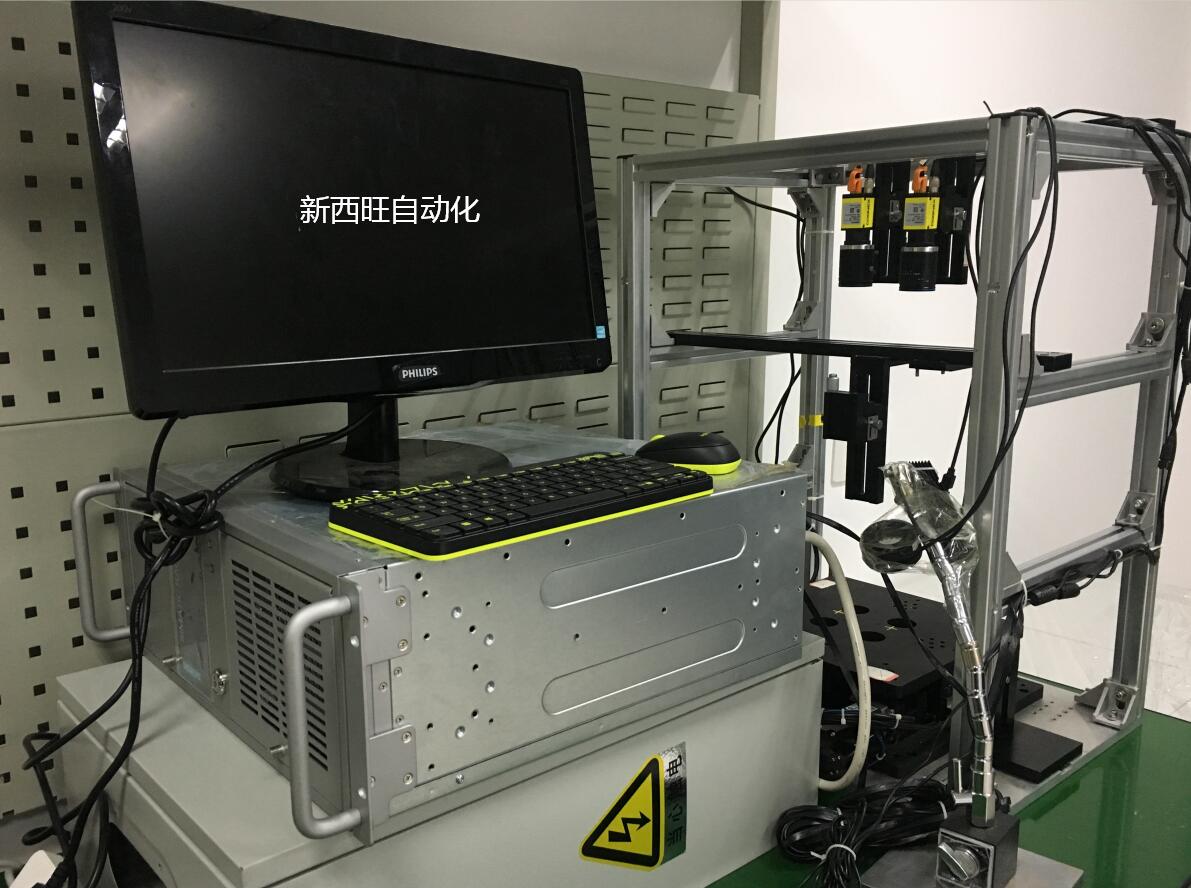

In the field of machine vision, CCD visual inspection equipment is mainly composed of: vibrating plate, industrial lens, operating table, display, and glass disc. Its product testing process is as follows:

1. The products are arranged in an orderly manner through the vibrating plate, conveyor belt or manipulator, and conveyed to the front end of the linear track.

2. Run through the conveyor belt or glass tray to drive the product to the camera and lens for inspection.

3. Imported industrial cameras are used to detect products and transmit clear pictures to the algorithm software.

4. Distinguish between good and bad products through algorithm software calculation and analysis.

5. The actuator of the pneumatic component equipment controls the on/off of the high-pressure air according to the instructions of the PLC, blows the defective products detected by the algorithm into the NG receiving device, and blows the good products into the good product receiving device.

Features of CCD visual inspection equipment

1. High detection accuracy

2. Fast detection efficiency

3. High accuracy

4. Automatic loading and unloading

Maintenance of CCD visual inspection equipment

1. In order to avoid the danger of rust or electric shock on the machine, it is strictly forbidden to drip water on the machine during the operation of the machine.

2. Regularly check the wear and tear of wearing parts such as glass plates, vibrating plates and sliders, and whether they need to adjust their clearances or replace them with new ones.

3. The installation and use environment of the equipment should be at room temperature and room temperature. High temperatures, high humidity, acidic and alkaline environments can affect the life and productivity of machine vision inspection equipment.

4. The indexing disc type optical inspection equipment needs to be regularly filled with lubricating oil to the divider to avoid damage due to lack of oil.

5. The factory should set up professional and technical personnel to manage the machine vision inspection equipment, and non-professionals are not allowed to adjust the camera at will, so as not to affect the detection accuracy.

6. Check whether there is water in the filter regularly and keep the filter dry.

7. When cleaning the device, be careful not to use tools that can damage mechanical surfaces, such as wire brushes, and do not use acidic solutions and plastic tools that are corrosive.

8. Regularly check the contact of electrical circuits, whether the wires are broken and aged, and clean up the dust in the motors such as industrial computers to avoid normal operation of the equipment.

9. The device needs to be cleaned regularly and the lens should be wiped regularly with a dust-free cloth. Regularly apply anti-rust oil to each component to prevent rust.

Chengdu Xinxiwang Automation Technology Co., Ltd. provides machine vision products (vision systems, visual light sources, industrial cameras, industrial lenses, vision software, vision sensors) and solutions, welcome to consult!

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu