In the automation industry, color is an important differentiating feature for many assembly verification and defect detection applications, and a single monochrome image is certainly not sufficient. To be able to implement an automated solution in a fast, easy, and more cost-effective manner, Xinxiwang recommended the Cognex In-Sight D900 color smart camera for inspection. Here are five common use cases that explain why color imaging is a key component in these inspection applications.

01. Impurity particle defect detection

Imagine trying to find a tiny orange rubber glove in the middle of a pile of brown food that is moving rapidly along a conveyor belt. This is nearly impossible for human quality inspectors and still difficult to achieve for monochromatic vision systems. But with the In-Sight D900 with color imaging, it's easy to identify foreign objects of different colors.

02. Verification of medical kit assembly

Assembled accessories (e.g., a medical kit containing syringes, bandages, and other supplies) may have similar-looking but very different items mixed in. If a medical kit contains syringes for different medications, such as flu vaccines, epinephrine, etc., it is common to choose to color-code the syringes to indicate their differences. However, when a monochromatic vision system validates, it treats these critical differences as the same. Only color images can further help ensure that similar-looking but different parts are correctly included in the kit.

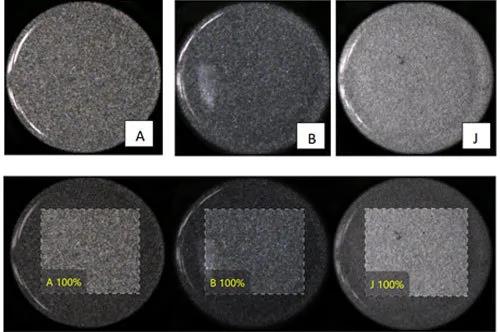

03. Rear auxiliary parking sensor inspection

Nowadays, most cars are equipped with cameras to help drivers stop or reverse, which is part of the car's standard safety gear. These cameras work by embedding sensors in the bumper, and manufacturers need to make sure that these sensors match the color of the bumper exactly. Many automakers have 25 or more varieties of sensor colors, including different shades of the same sensor color. This is a challenging test that is clearly only capable of deep learning and color imaging.

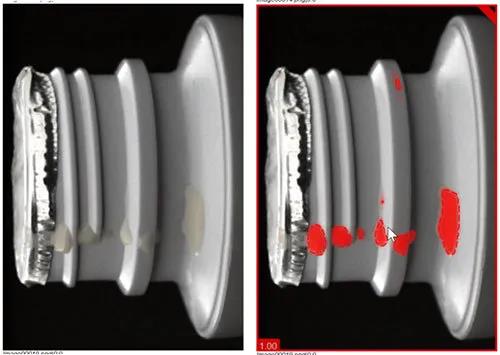

04. Detection of white objects overflowing on white bottles

Whether in consumer-packaged goods or in the food and beverage industry, manufacturers can find themselves with the challenge of inspecting liquid products that are the same color as the bottle. Without the use of color images, the detection system will not be able to identify the liquid spilled from the container because the liquid inside the container is the same color as the container.

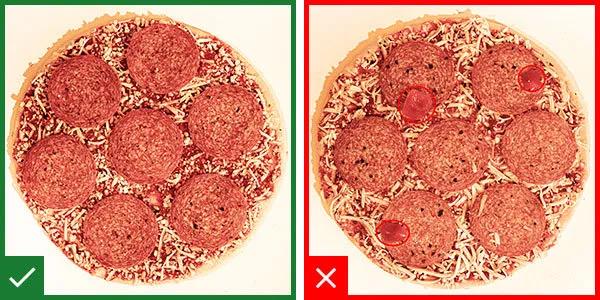

05. Identify the correct frozen pizza filling

Nowadays, fast food is becoming more and more popular among consumers. Who doesn't love a frozen pizza when they're hungry late at night, especially a crayfish pizza, but you don't like to unpack it only to find that the pizza is full of green peppers and the crayfish are pitiful. When frozen pizza is inspected on a conveyor belt, the black-and-white image will make it difficult to determine if the correct toppings have been added, especially if unwanted toppings have been accidentally added to the pizza. As a result, color imaging allows frozen pizza inspectors to ensure that the crayfish is really crayfish and not green peppers or any other unwanted toppings.

In addition to these use cases, the Cognex In-Sight D900 color smart camera is also ideal for industries that rely on automated color inspection applications, including automotive, consumer electronics, consumer goods, packaging, food and beverage, medical devices, and logistics. If you want to think about the price and visual inspection plan of Cognex products, you can call the Xinxiwang hotline: 028-62705808 We will answer for you!

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu