To keep up with the growing demand for vaccines, Cognex offers a complete suite of machine vision, deep learning, and barcode reading systems to automate vaccine packaging inspection, tracking, and distribution. Helping vaccine suppliers navigate stringent regulatory regulations and safe, fast, and reliable delivery methods.

Step 1: Primary packaging inspection

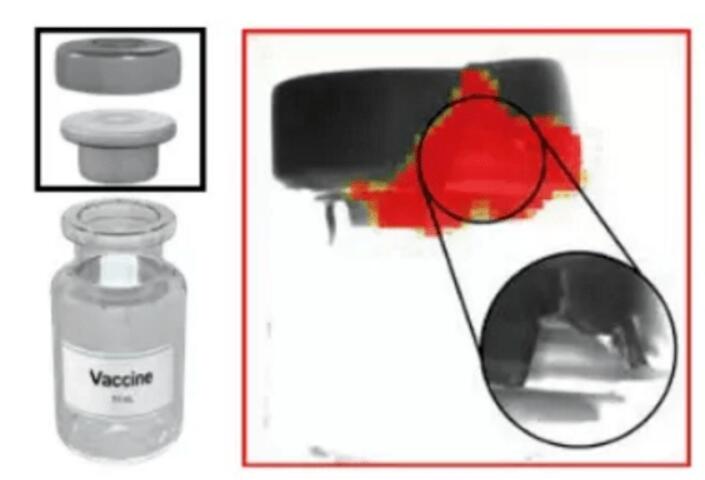

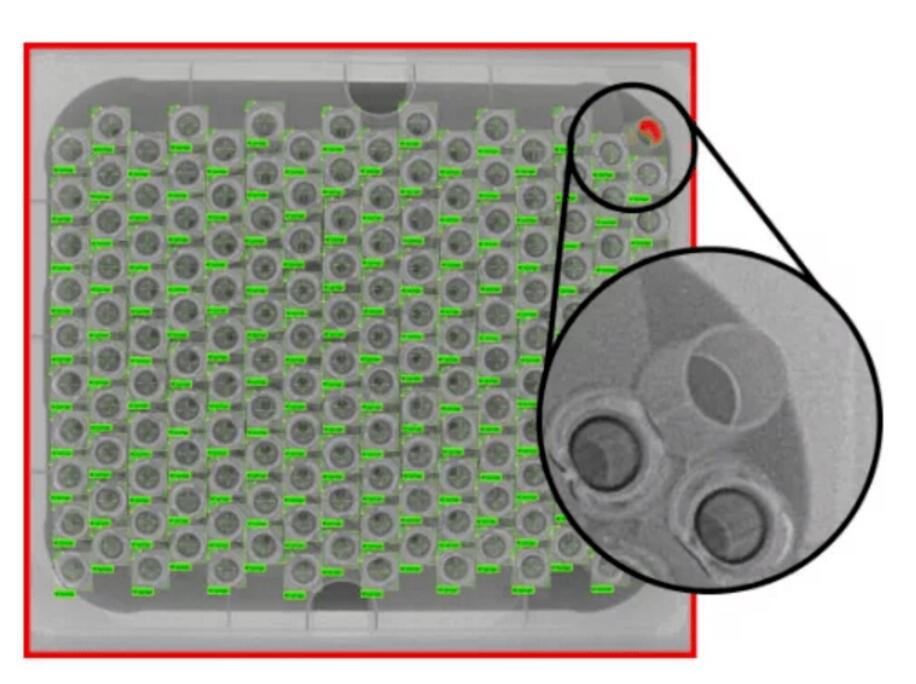

1. Vial capping, crimping and bottle stopper inspection

Machine vision and deep learning systems can help detect vial closures for scratches, punctures, and other defects to improve product quality, significantly reduce product scrap, and increase throughput.

2. Detection of vials and ampoules

Deep learning systems can help detect vials and ampoules for scratches, bubbles, inclusions, and more, avoiding defects that could contaminate the contents or destroy sterility.

3. Particulate matter detection

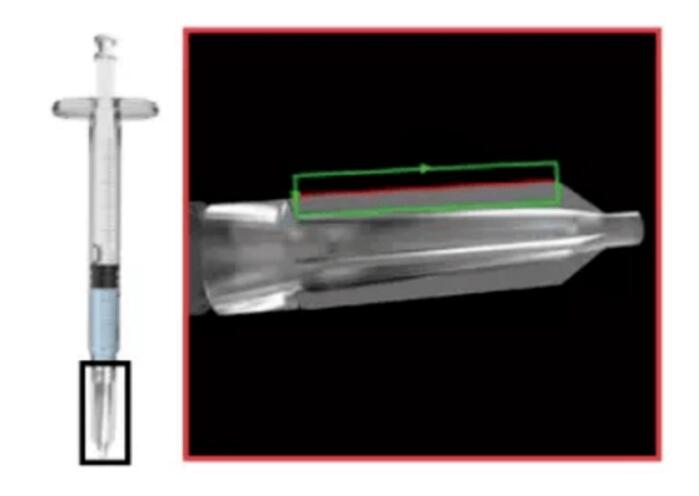

4. Syringe flange detection

5. Syringe needle cap detection

Machine vision systems can help inspect and measure the position, straightness, and other characteristics of needle safety guards to ensure proper syringe assembly.

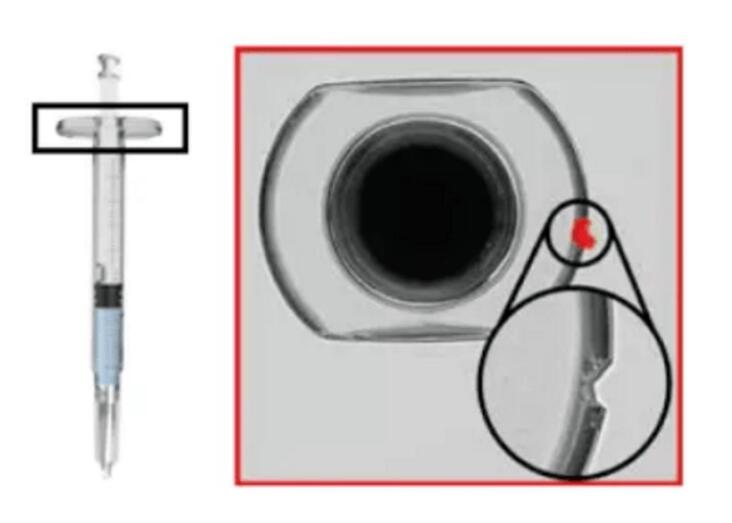

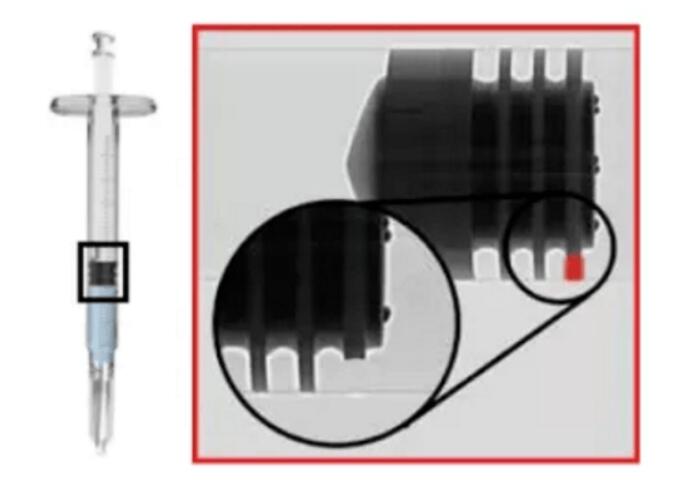

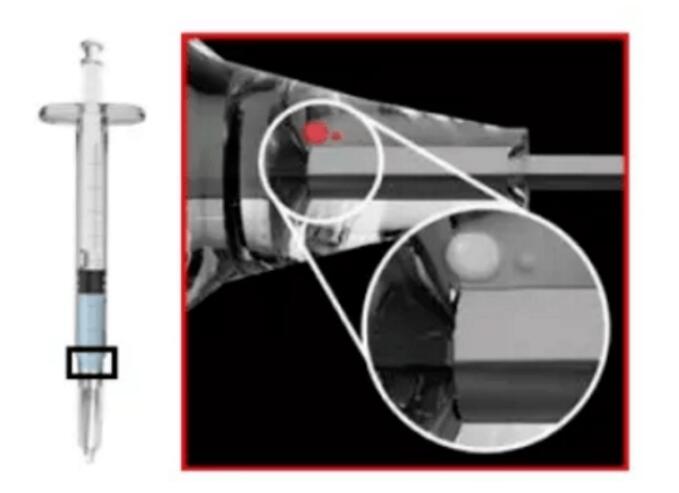

6. Syringe plunger stopper detection

Deep learning systems can help detect whether the stopper's ribs are torn, fluid is present between the ribs, and cracks occur during the insertion of the stopper into the syringe barrel.

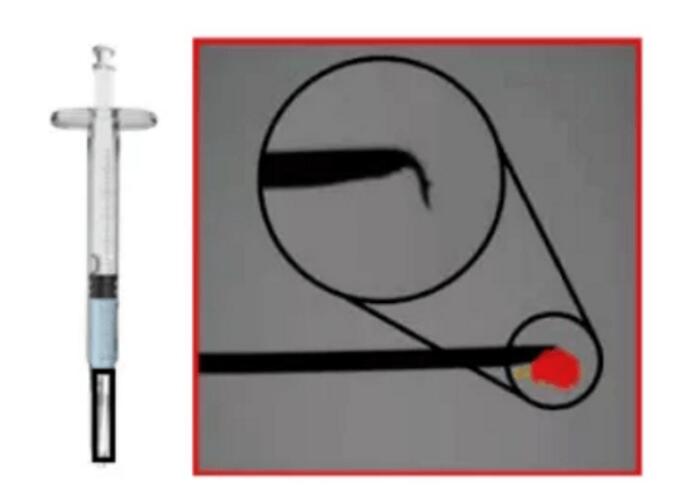

7. Syringe needle detection

Deep learning systems can help detect subtle defects in syringe tips that have been beveled-edge grinding to protect patient safety and ensure proper vaccine injection.

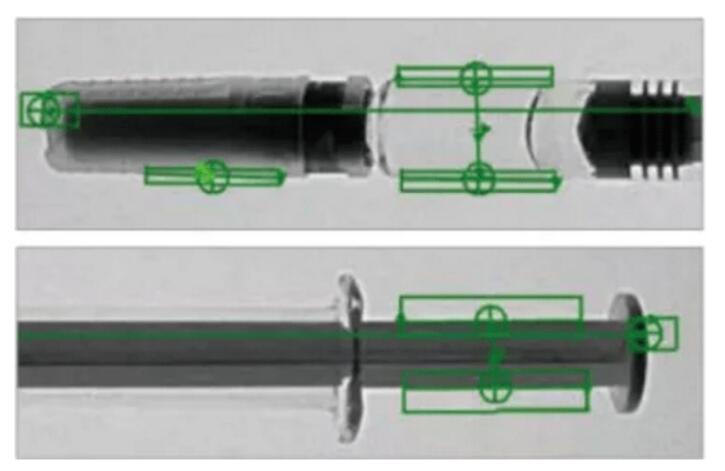

8. Verification of needle and syringe assembly

Deep learning systems can inspect needle and syringe assemblies for air bubbles, cracks, insufficient needle adhesive usage, cone problems, or other inclusions.

9. Size detection of prefilled syringes

Machine vision systems can help inspect syringe barrel length, plunger length, flange thickness, inner and outer diameter of the cylinder to ensure that the syringe meets specifications.

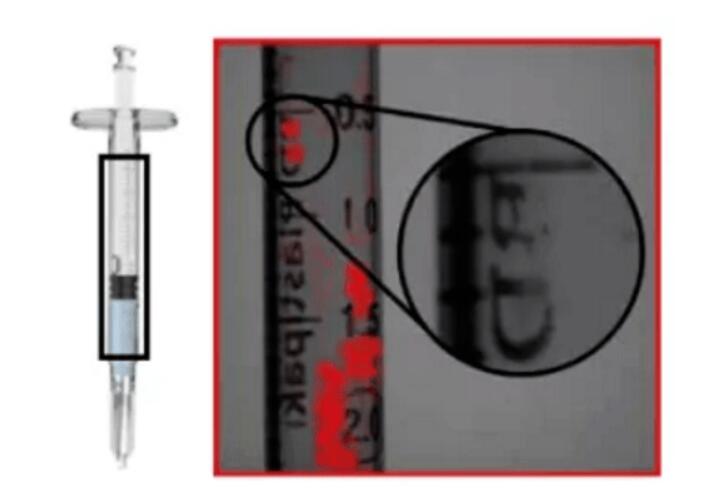

10. Pad printing detection of prefilled syringes

Step 2 – Secondary packaging inspection.

Secondary packaging testing of pharmaceutical vaccines usually involves the following steps, and only by ensuring the safety and error-free of these links can these products be used on patients with confidence.

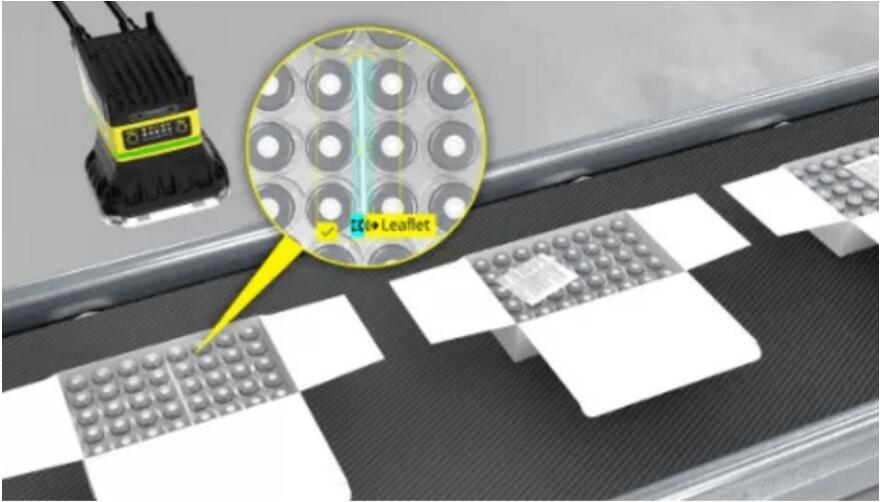

1. Vial and ampoule counting

Deep learning systems can eliminate the bias associated with counting, preventing time-consuming and costly rework due to counting errors.

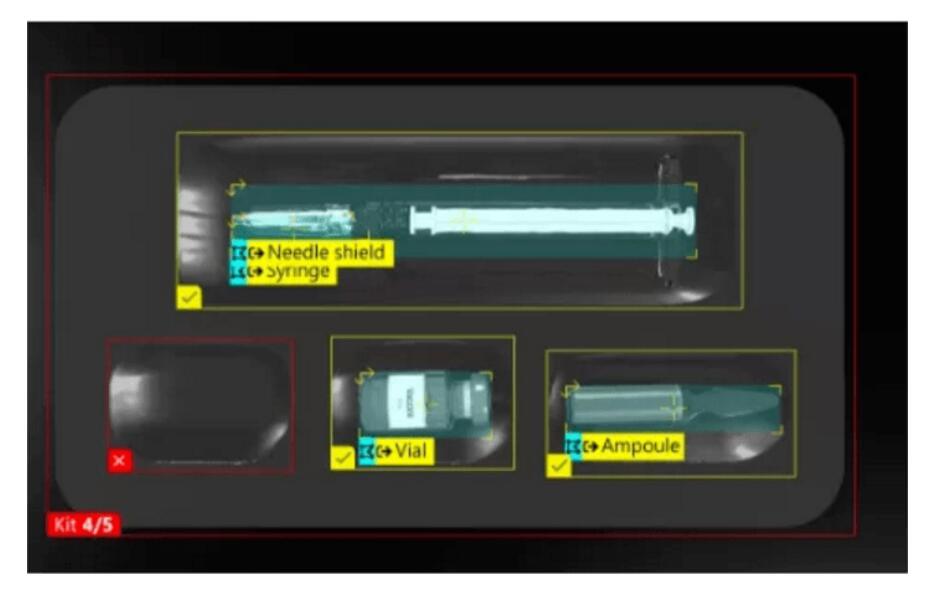

2. Verification of vaccine tool packaging and matching

Deep learning systems can detect vaccine kits for issues such as overlapping and missing components, and ensure that the correct components are present and placed in the right direction.

3. Confirm the patient's information on a single page

4. Label integrity testing

Deep learning systems are able to locate, capture, and classify broken or voided seals, inadequate seals, and other anomalies in a variety of directions to prevent product contamination.

5. Phase III testing of vaccine packaging

Deep learning systems read information printed on packages and verify the quality of mandatory printed elements such as logos, date/lot information, and other graphic information.

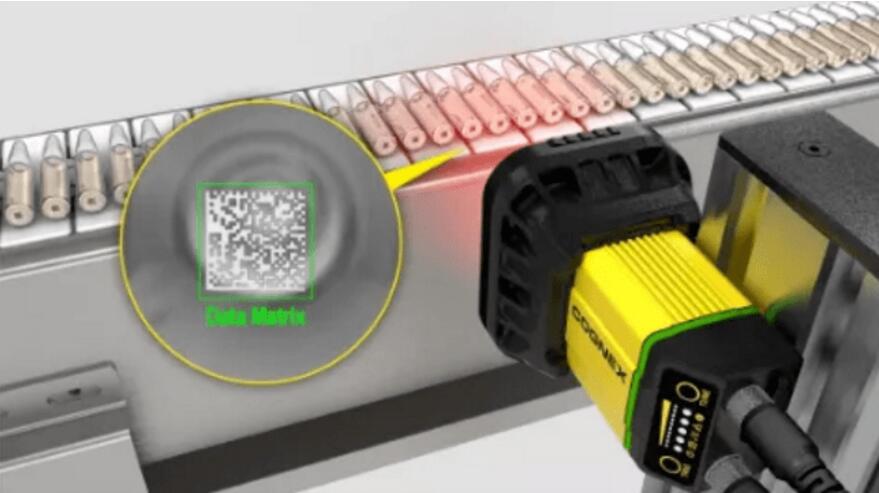

6. Vaccine code reading

Machine vision barcode readers are capable of reading 1D and 2D barcodes as small as 3 mils on medical devices to track and trace products and help combat product counterfeiting.

7. Vaccine code verification

Machine vision code verifiers provide true ISO compliant online or offline code verification and generate detailed code quality reports to ensure traceability, compliance, and preventative maintenance.

Step 3 – Track the whole process of vaccine warehousing and distribution

1. Cold chain storage and distribution

Machine vision fixed image-based barcode readers significantly reduce package contact and quickly assign delivery paths for perishable vaccines and drugs.

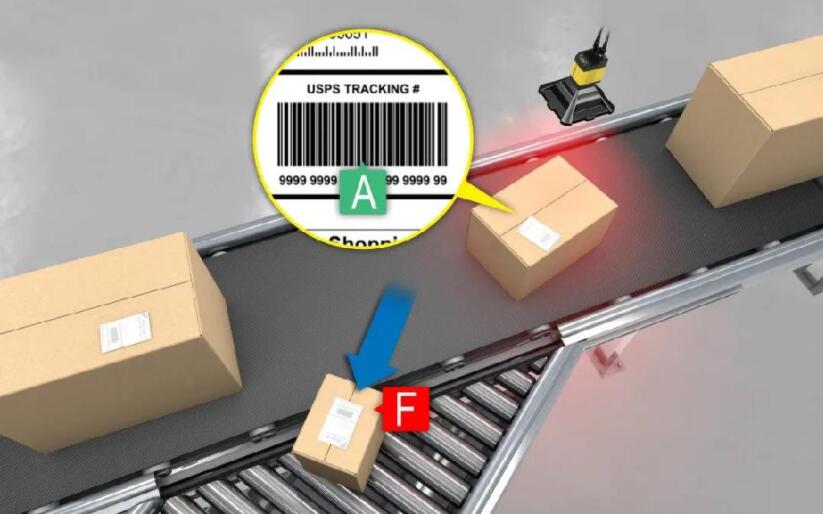

2. Path allocation

Even if the product code is worn or damaged, or the code position and orientation are variable, machine vision fixed-mount barcode readers reliably steer the case to the correct aisle or area.

3. Label verification

Machine vision barcode readers and verifiers ensure that each shipping label is printed and applied correctly and that complete information is included to ensure end-to-end traceability.

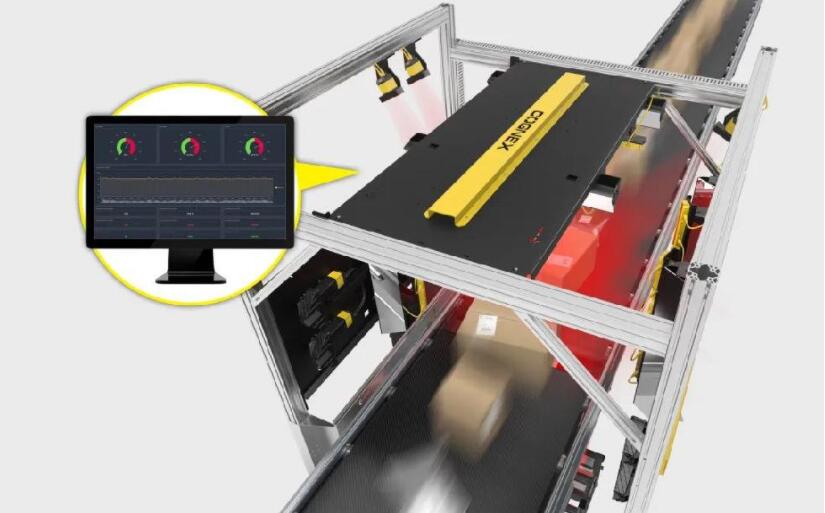

4. Parcel sorting

The machine vision five-sided barcode reading lane solution accurately sorts packages and transports them quickly to their final destination, significantly reducing delays.

5. Warehousing processing

Cognex DataMan 370 Series image-based barcode readers reliably read codes on packages, ensuring efficient receipt of incoming goods, unpacking of goods, and distribution of conveyor paths.

It can be seen that Cognex has guarded the whole process of vaccine production, avoiding the huge pressure and production efficiency faced by vaccine suppliers.

Disclaimer: Some of the content and pictures in this article are from the Internet, which is only for the purpose of academic communication. If there is anything wrong, please contact us to delete it.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu