In daily life, no matter what you buy, you will generally have a choice, such as: shop around, especially when buying those large and valuable items, you will be cautious, after all, these are bought at a high price. The same is true for optical image screening machines, and the following Xinxiwang will explain to you the preparations you need to make before purchasing an optical screening machine:

1. Collection of samples

Samples are collected in two categories: good and bad. There can be several good products, and bad products can be divided into a variety of defects, such as notched, burrs, black spots, clogged holes, crushes, deformations, etc. The number of defective products should be larger, packaged by category and marked with which defective they belong to, so that the supplier can make proofs.

2. The determination of accuracy

Customers often believe that the higher the accuracy, the better, and the smaller the defects that the device can detect, the better. In this way, can't we achieve zero defect factory? In fact, the equipment is not omnipotent, the optical screening machine is not a microscope, and it cannot achieve the accuracy of a microscope. The higher the accuracy, the better, but the appropriate accuracy is chosen, otherwise a large number of defective products will be generated. For example, when manually screening product gaps, gaps within 1 mm can be missed, and the accuracy range can be set to within 1 mm. If the accuracy is set too high, it is easy to cause waste. If the accuracy is set too low, the optical screening machine will judge the manually screened defective product as good, resulting in false detection. Some products have high requirements for accuracy, and need to reach an accuracy range of 0.001mm, which cannot be measured manually. At this time, the role of the optical screening machine becomes very important.

3. Determination of output

The main purpose of purchasing equipment is to improve production efficiency. If the product output is small and the efficiency requirements and quality are not high, then manual inspection is a better choice. If a product requires more than three people to inspect, then it is necessary to choose an optical screening machine.

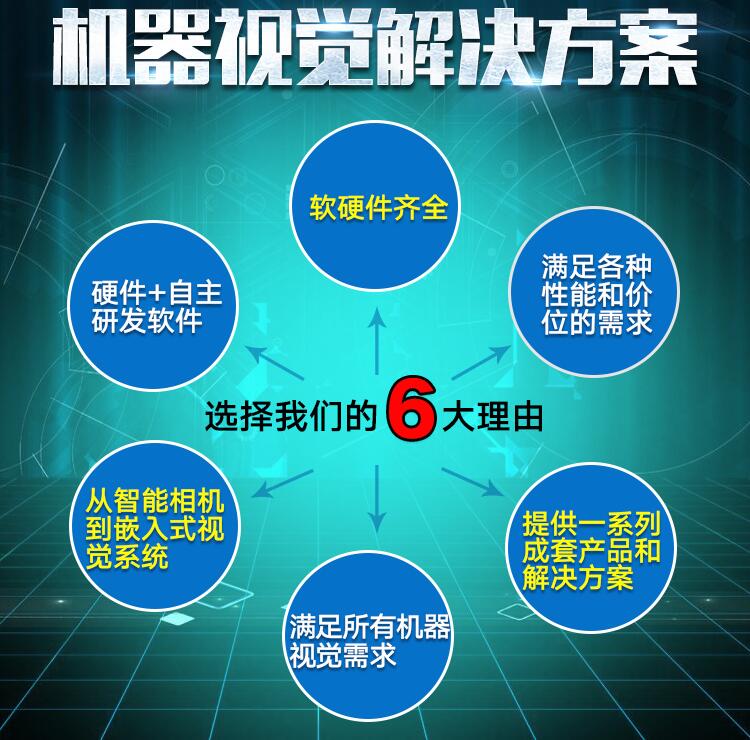

Chengdu Xinxiwang focuses on machine vision inspection, specifically for the needs of different customers in machine vision inspection, providing professional detection, measurement, guidance, positioning and other visual solutions, for customers to enhance the company's competitiveness, improve the automation level of the factory and product quality.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu