With the resurgence of the epidemic, in addition to wearing masks, measuring body temperature, reducing gatherings, washing hands frequently, disinfecting frequently, and ventilating frequently, mask quality testing and vaccine packaging testing to prevent the spread of diseases are also crucial, because it is about people's lives. In order to avoid defective products from entering the market, Cognex offers effective solutions for mask quality testing and vaccine packaging testing.

Mask quality inspection: machine vision & deep learning, escorting people's travel

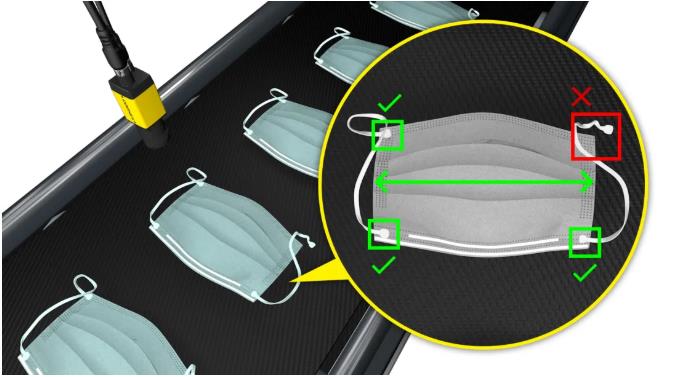

Cognex In-Sight 8402 vision system Mask components can be inspected for defects, such as ear straps and joint points, and the width of the mask can be measured to ensure that it is the correct size. Many defects are difficult to predict and program with traditional machine vision algorithms, and Cognex Deep Learning can easily locate and classify random defects, such as tears, stains, and sewing errors, using only 50 sample images to ensure the quality of the mask and make it protective.

Vaccine packaging testing: Ensure that vaccines comply with regulations and are delivered safely, quickly, and reliably

Pharmaceutical manufacturers are also under tremendous pressure to produce and distribute vaccines in large quantities in vials, ampoules and prefilled syringes. To keep up with growing demand, manufacturers are relying on machine vision, deep learning, and industrial barcode reading systems to automate vaccine package inspection, tracking, and distribution. Whether the vaccine is being supplied for standard immunizations or in the fight against a large outbreak, Cognex solutions help vaccine suppliers meet stringent regulations and ensure safe, fast, and reliable delivery.

■ Primary packaging: Machine vision and deep learning systems can detect products for cracks, particles, incorrect assembly, and other potential defects during the primary packaging process. Identifying issues early upstream in the production line can help ensure patient safety and avoid costly product recalls and returns.

■ Secondary packaging: Cognex technology can confirm that vaccine boxes and kits are properly packaged and comply with strict regulatory regulations, and help pharmaceutical manufacturers track and trace suppliers to ensure machines remain up and running, achieving high read rates and fast delivery.

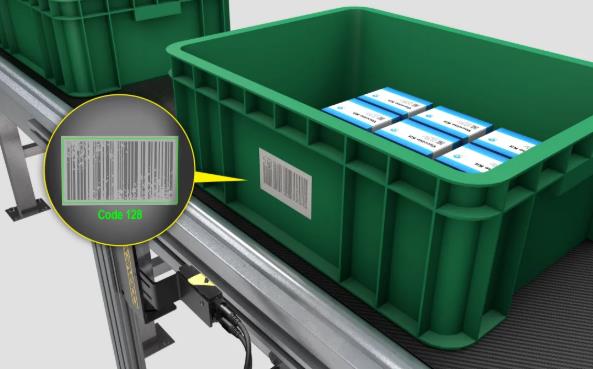

■ Warehousing & Distribution: Vaccine distributors rely on image-based barcode readers to track and trace products throughout the supply chain, ensuring that the vaccines ordered by customers reach their intended destination quickly and efficiently. Missing, incorrect or late deliveries of ordered items may affect vaccine efficacy, resulting in customer returns and product scraps. Cognex barcode readers can track vaccines from the manufacturer to the point of care to ensure accurate, just-in-time delivery and help manufacturers prevent counterfeit products from reaching consumers.

If you want to know more about more detailed machine vision inspection solutions and machine vision products, you can call the Xinxiwang hotline: 028-62705808

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu