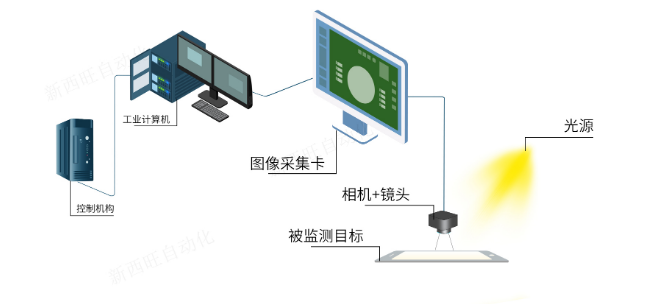

AOI is the full name of automatic optical inspection system, which is composed of industrial cameras, industrial lenses, visual light sources, computers and other general devices integrated simple optical imaging and processing system. Under light source illumination, the camera is used to image directly, and then the detection is realized by computer processing. The advantages of this simple system are low cost, easy integration, relatively low technical threshold, and can replace manual detection in the manufacturing process to meet the requirements of most occasions.

AOI visual inspection equipment can provide offline and online inspection solutions according to customer needs, in order to improve production efficiency and welding quality, reduce costs, and ensure the final quality of products.

Working characteristics of AOI(Automatic Optical Inspection equipment)

1, the detection speed is very fast, and is not affected by the mounting density;

2, fast and convenient editing system, graphical interface, what you see, the use of mounting data for automatic detection program preparation;

3, for different detection items, combined with optical imaging processing system, there are different detection methods (detection algorithms);

4. When the mounting position of the tested component is offset, the detection window will be automatically positioned to achieve high-precision detection;

5, display the actual error image, convenient for workers to carry out the final visual inspection;

6, statistical NG data analysis of bad causes, real-time feedback process information.

Application areas of AOI(Automatic Optical Inspection Equipment)

The general process of AOI detection equipment is the same, mostly through graphic recognition. The standard digital image stored in the AOI system is compared with the actual detected image to obtain the detection result. AOI inspection equipment is an automatic optical inspection device used in surface mounting production line. Can be very efficient detection of printing quality, mount quality and solder joint quality. By using AOI as a defect reduction tool, errors are identified and eliminated at the beginning of the assembly process to achieve good process control results. If defects can be detected at an early stage, it can avoid sending defective products to the assembly stage of the later process. AOI electrical measuring machines will reduce repair costs and will avoid scrapping unrepairable circuit boards.

As a technology enterprise focusing on research and development, Xinxiwang has independent research and development of core technology achievements in image algorithm, calibration algorithm, alignment algorithm, automation and other aspects: high-precision alignment system, AOI detection system, BC system, code-reading automatic Posting system, etc., to provide core machine vision technology for the core screen construction of China 2025 intelligent manufacturing Industry 4.0.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu