In machine vision inspection, the use of light source directly determines the detection effect, then how to choose the appropriate light source? What needs to be considered?

1. Characteristics of the object to be measured

The purpose of lighting is to highlight the detected object and improve contrast, so the characteristics of the measured object are selected reference points. It takes a lot of experimentation and experience. For example, scratches on a smooth surface need to be grazed at a low Angle so that the light reflected from the surface cannot enter the lens, and imperfections such as scratches will change the direction of the light, resulting in a prominent feature on a black background with high contrast that is easy to handle.

2. Working distance

5mm and 500mm distance of the light source is obviously impossible to be the same, the distance of the light source to the object determines many indicators of the light source, for LED particles, illuminance and the square of the distance is inversely proportional, under normal circumstances, illuminance can be used to approximate this law.

3. Field of view size

The light source used to form a uniform viewing spot with a 50mm diameter and a 500mm diameter will not be the same. And the same field of view size, for different measurement targets, the choice is also different. If you only measure a target above a ring, then maybe a ring light source can be used, and if you want to measure a target on a surface and want uniform lighting, then maybe a four-sided shadowless light source is a better choice.

4. Installation method

How to install on the mechanical structure, how much installation space for the light source? At this time, you need to consider the installation of the visual light source.

5. light source color

Generally speaking, machine vision projects are based on black and white cameras, because the image processing function for grayscale, binary image function is much more than the color image. Some projects don't have too many requirements for camera color. Therefore, if there is no special need to use a black and white camera to meet the requirements, consider using a monochromatic light source such as red, green, blue and so on. Because the monochromatic light source has a single spectrum, the color difference is almost eliminated, so its imaging is better than the white light source used by color cameras.

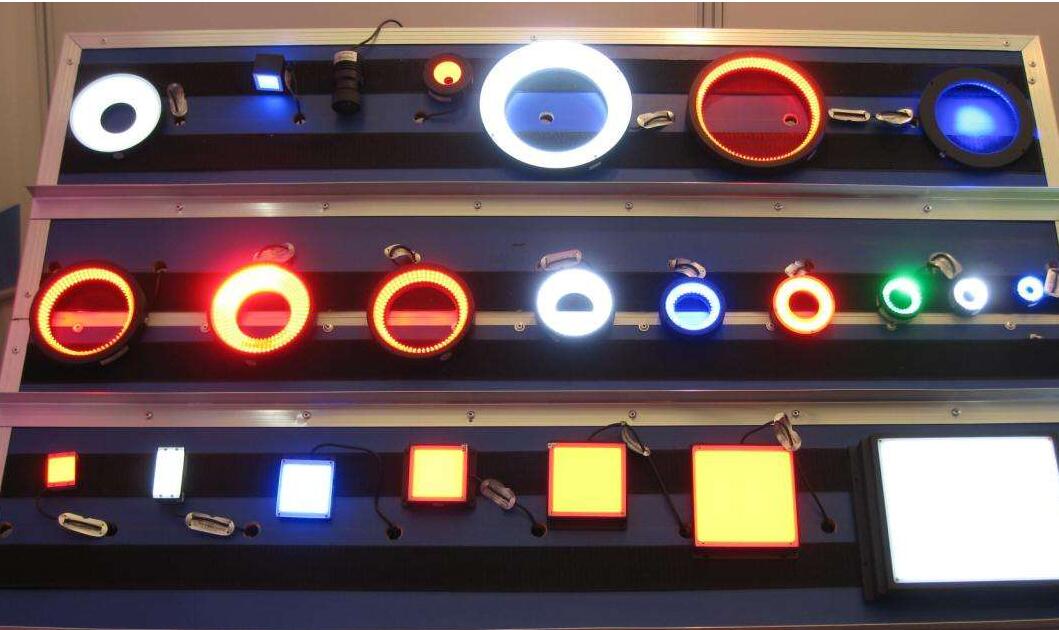

Light source selection scene:

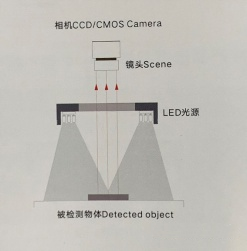

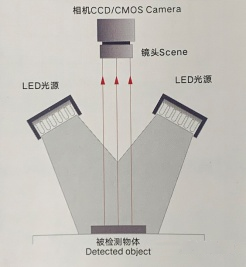

Scene 1. Detecting defects such as surface scratches, scratches, and character quality

The detection of scratches and bumps on the surface of parts, whether the printed characters are missed, multiple printing and other such surfaces are relatively flat and the scene with small reflection is generally treated with a ring light source, which can provide different irradiation angles and color combinations as well as three-dimensional information of the object.

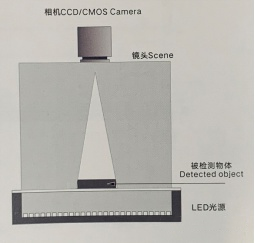

Scenario 2. Measuring profile dimensions and detecting edge damage

To confirm the size or shape of the parts outline, it is necessary to observe the edge shape of the parts; Such as ceramic contour detection, stamping hole quality detection, etc., the backlight is generally used for lighting treatment.

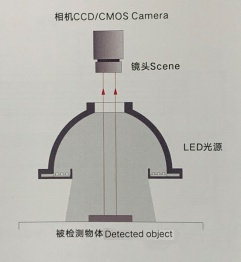

Scene 3. Defect detection of curved, concave and convex surfaces

For parts with uneven surfaces and a certain arc, the dome light source is generally used for defect detection.

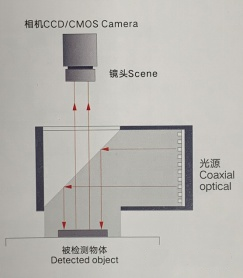

Scene 4. Surface defect detection of highly reflective objects

For the surface defect detection of metal, glass, ceramics and other highly reflective objects, the general lighting will produce strong reflection, resulting in some areas are not visible, and it is necessary to use a coaxial light source for defect detection.

Scene 5. General Appearance Check

For the appearance defect detection of textured and relatively flat large-area parts such as metal surface scratches and cracks, strip light sources are generally used.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu