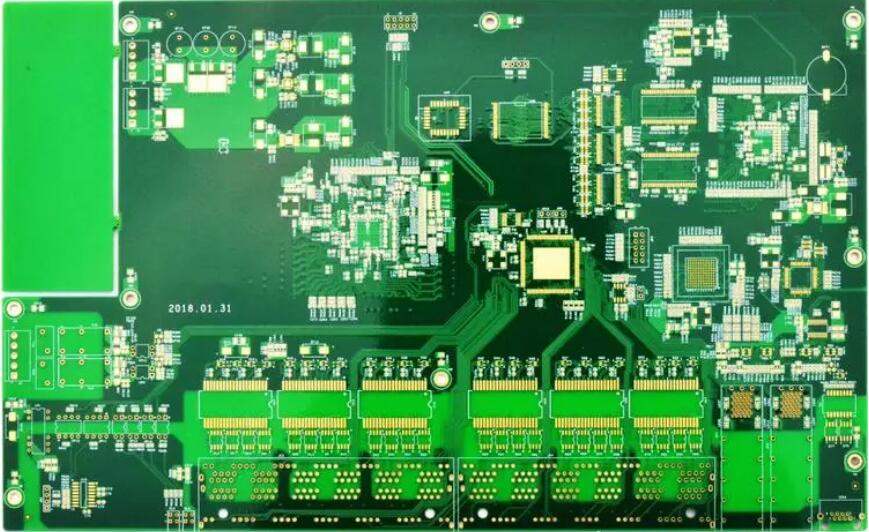

With the development of technology, PCB board, as an important part of modern electronic equipment, is an information carrier integrating various electronic components, and has a wide range of applications in the field of electronics, and its quality can directly affect the performance of the product. With the PCB increasingly ultra-thin, high-density, fine spacing, PCB circuit board components on the line width, spacing, etc., has reached the micron level, the traditional manual detection method is easy to miss, the detection speed is slow, the detection time is long, the cost is high, has gradually failed to meet the needs of production testing. Therefore, using a machine to replace the human eye for measurement and judgment - machine vision detection technology as a substitute for traditional manual detection, has very important practical significance. What can machine vision detect on the PCB?

1. Recognition classification detection

Through visual detection of PCB shape, size, inner hole, and matching with the black and white feature map of the product loaded into the system to identify the board number.

2. Borehole coding inspection

The drill marks are decoded according to the coding rules.

3. Pad appearance inspection

In the PCB production process, there will be a phenomenon of pad cover oil after the development line, and timely detection of the problem at this station can reduce the following series of processes and save costs.

4. Character read detection

Detect whether the PCB character code form meets the standard, whether it is clear without missing, whether the line is smooth without convex points, whether there are defects such as line weight, double shadow, pitting, deformation, color difference, offset, misprinting and so on.

5. Appearance inspection

Machine vision inspection technology, including PCB, BGA, pin and patch detection, as well as solder joints, missing components, orientation errors and other aspects of integrity detection. For example, whether there are stains, debris, pits, tin residue on the surface of the PCB board; The clarity of surface characters and symbols; Whether the tin on the pad is uniform, etc.

Compared with traditional inspection methods, machine vision inspection has unparalleled technical advantages, such as high precision, fast speed, high efficiency, non-contact measurement, etc., which is widely used in PCB inspection.

Notice: This picture is from the Internet, if there is any infringement, please contact to delete.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu