Company introduction

Chengdu Xinxiwang Automation Technology Co., LTD., founded in 2015, is a focus on panel display, new energy, semiconductor industry machine vision application partner, machine vision inspection product provider, machine vision overall solution provider, national high-tech enterprises, national specialized special new small giant enterprise, annual output value of more than 100 million yuan.

The company has set up branches in Shenzhen, Changsha and Chongqing; We have offices in Mianyang, Wuhan, Wuxi, Gu 'an and Hefei. The existing staff of more than 190 people, R & D team including dozens of doctors, masters and industry senior experts, has rich experience in the development and application of machine vision industry, with a number of independent research and development of core technology achievements: high-precision alignment system, AOI detection system, data information system, intelligent detection equipment. Xinxiwang has provided professional overall machine vision solutions and services for thousands of enterprises in the field of global intelligent manufacturing.

Application background

With the improvement of the intelligence and automation of lithium battery manufacturing, machine vision products have begun to be widely used in various sections of lithium battery equipment production. GGII after investigation and calculation, battery single GWh production line for machine vision demand value of about 7 million yuan, according to the current expansion plan of various battery manufacturers, by 2025 production capacity is expected to exceed 2TWh, compared with the current production capacity, not put into production capacity accumulated more than 1300GWh, among them, the potential unreleased machine vision order demand exceeds 9 billion yuan. From the front, middle and rear stages of the cell production process to the module PACK segment, machine vision is widely used, and the improvement of permeability has significantly improved the quality control of lithium batteries.

The use of machine vision can avoid pollution caused by manual operation, and can timely detect and intercept the flow of defective products to the terminal. In addition to improving quality control, the analysis of defect measurement data through vision software and algorithms can further provide data support and decision-making basis for process improvement direction and quality optimization of battery enterprises. Many application advantages have brought about a rapid increase in the application scale of machine vision products in lithium battery manufacturing.

Die-cutting machine to achieve a device to complete the laser cutting pole ear + slitting production function, a one-time solution to the pole ear high-speed forming, pole slice slitting, is a lithium battery pole slice in the slitting process is a very key equipment, it is efficient, accurate and intelligent characteristics become a productive assistant, is to improve production efficiency, reduce labor costs, and ensure the stability and consistency of product quality is a key link. In the production, there will be defects in the pole plate, the pole ear, the pole ear width is different, and the AT9 width is different. Cause a lot of waste of products. The visual camera is used for real-time inspection, and the appearance of the segmented pole slice is also detected. The whole process does not require manual operation, automatic detection, automatic closed-loop.

System introduction

Die-cutting machine in the production process need to carry out cutting positioning and correction, size measurement, defect detection, cutting may appear polar plate defects, polar ear defects, polar ear width, AT9 width is different, resulting in a lot of waste of products. Die-cutting a machine vision inspection system is a set of the company's technical background and rich industry experience, according to the characteristics of the lithium battery industry and the slitting machine vision inspection needs to provide the overall machine vision solution, can meet the die-cutting positioning, pole ear size detection, slitting size detection, correction, surface detection and other customer needs. The traditional vision algorithm and AI vision optimization deep neural network algorithm are deeply integrated, so that defects have nowhere to hide.

System composition

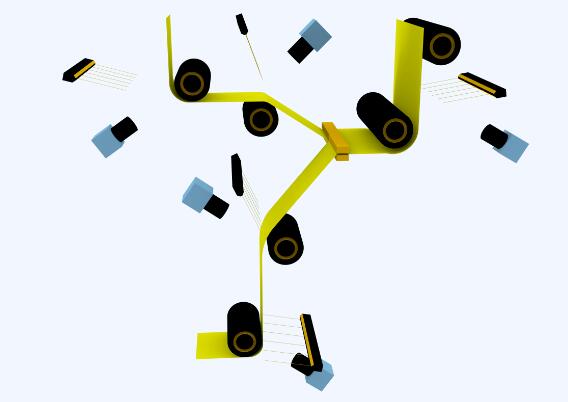

Die-cutting machine intelligent vision overall solution, the integration of intelligent hardware, leading vision algorithms, complete industry experience, including the perception layer, platform layer, application layer. The visual solution idea of formalized inspection requirements, combined with a complete visual solution, can meet the changing inspection needs in production.

Xinxiwang AI intelligent standardized vision overall solution - die-cutting and slitting machine application case (Figure 2)

As the "eye of the machine", the perception layer realizes accurate imaging through unique optical scheme and perfect visual hardware, laying a good foundation for visual detection.

The platform layer is a configurable vision platform built with AI deep learning as the core, integrating 2D and 3D traditional vision algorithms, deep learning vision algorithms, and self-developed vision algorithms for lithium battery characteristics. Rapid deployment to meet production requirements, simple interface, easy maintenance, and fast migration online.

The application layer includes a soft and hard integrated quality inspection system, visual terminals, etc., which can be embedded in the customer's production system and serial peripheral equipment to realize the intelligent upgrade of the quality inspection production line.

Detection requirement

After die cutting, real-time detection of the electrode size, defect detection, spacing measurement, electrode cutting depth detection, real-time detection of the width after the strip, feedback equipment real-time correction, surface defect detection. Defects include metal leakage, bubbles, dark marks, decarburization, damage, scratches, black spots, white spots, tape, etc., and are classified, connected with the labeling machine, and labeled in the designated position of the defective product.

Solution

Xinxiwang AI intelligent standardized vision overall solution - die-cutting and slitting machine application case (Figure 3)

In the field of perception layer, the system solution uses high-speed, high-pixel, high-performance visual acquisition hardware, coupled with high uniformity, good stability, and bright light sources to achieve accurate imaging.

In the platform layer, self-developed algorithm AI deep learning is the core, subpixel edge contour extraction technology of Xinxiwang patented technology is adopted, and subpixel edge point detection method based on Gaussian model convolution is adopted. Edge point detection of edge images of any intensity can be carried out by setting the convolution kernel width, effectively improving the detection accuracy of subpixel edge points and algorithm robustness.

The hardware with high performance and strong computing power in the application layer is combined with the visual terminal interface, which can be embedded in the customer's production system and serial peripheral equipment to realize the intelligent upgrade of the quality inspection production line.

Advantages and characteristics

With excellent defect understanding + highly robust self-developed algorithm, Xinxiwang intelligent solutions can meet the needs of high-speed inspection in the industry, complete the rapid deployment of new inspection needs, and solve production problems.

➤ Customized visual terminal interface for easy production;

➤ Standardized visual solutions, rapid deployment, whole-line migration and replication, to help customers seize market opportunities;

➤ Self-developed algorithm for industry characteristics can meet the detection speed of ≥150m/min, and the accuracy rate is ≥99.9%.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu