Background

With the widespread use of new energy, battery quality has gained attention: coating width too small or too large affects the energy storage capacity of the battery; defects in the electrode sheet may impact the battery's functionality and, more seriously, can lead to safety issues; the battery cell packaging and electronic surface features can be confusing. Xinxiwang’s Vision Inspection is widely used in quality inspection of various processes of new energy batteries to improve product quality, such as coating width, coating quality, battery cell defects detection, one-dimensional and two-dimensional code reading, measurement of the relative height from the top cover to the shell before welding, and inspection of the welding quality on the inner side of the top cover.

System Performance

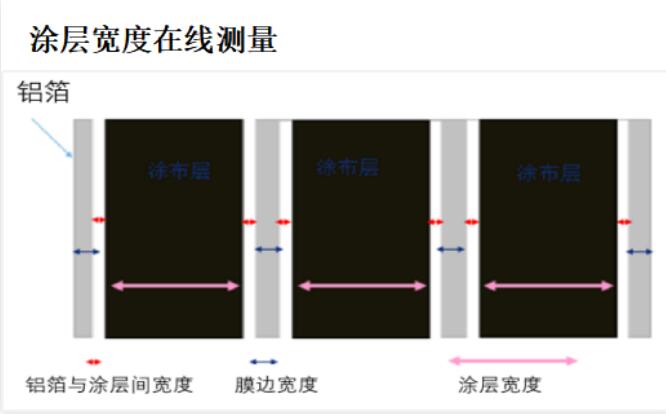

Online measurement of coating width

- Real-time measurement of coating width and the distance from the coating to the edge.

- Speed: 600mm/s.

- The maximum width of the coating is 680mm.

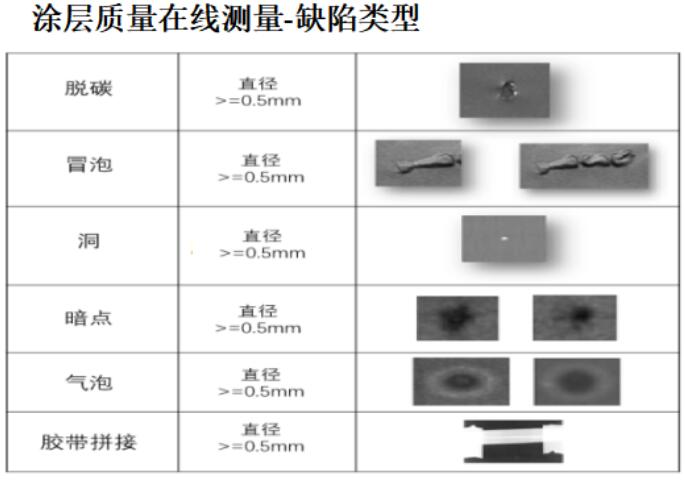

Online Coating Quality Inspection, Real-time Defect Detection

● When defects are detected, the vision system outputs an NG signal to the PLC, which will drive the printer to affix a yellow label near the part marking.

● Label placement accuracy is ±5mm, label size is 20*40mm,

● Distance from label to marking hole is 50mm.

● Speed: 750~116mm/s.

● Pass rate: <1%.

● Failure rate: 0%.

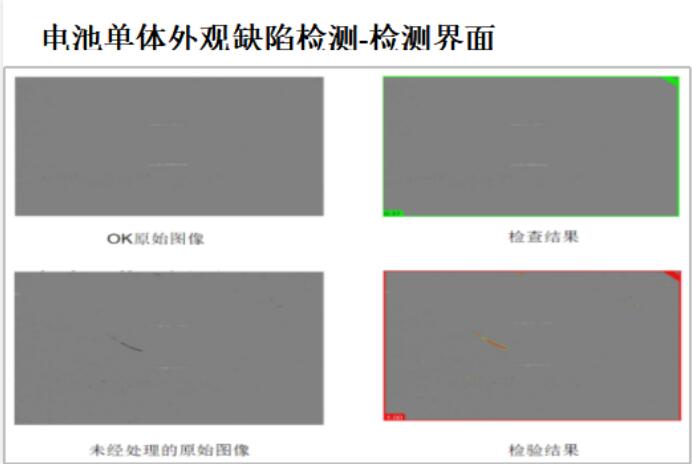

Battery Cell Appearance Defect Detection

Pinhole: 0.5*0.5*0.5mm

Sunspot: 0.5*0.5*0.5mm

Scratch: 0.5*20mm

Inspection Time: <0.5s

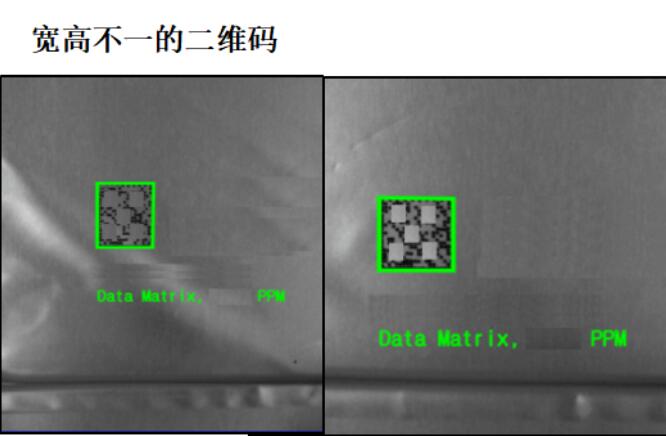

1D and 2D Code Reading

The Xinxiwang’s Vision code reading system can read 1D and 2D codes, even if they are uneven due to inconsistent inkjet printing speed, leading to variations in code width and height.

Reading Rate: >99.5%

Reading Speed: <500ms/pcs

Application Field

New Energy Battery Inspection

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu