Project Background

After electroplating, various defects can appear on the surface of the shock absorber link's chrome-plated layer, such as dot-like dents, dot-like dimples, localized black spots, linear scratches, cracks, irregular scratches, irregular cracks, linear or dot-like impact damage, electroplating blister defects, and electroplating pinhole defects. Manual visual inspection can lead to fatigue, and some smaller defects are prone to be missed. Therefore, in order to improve accuracy and reduce labor costs, a vision-based inspection method is employed for detection.

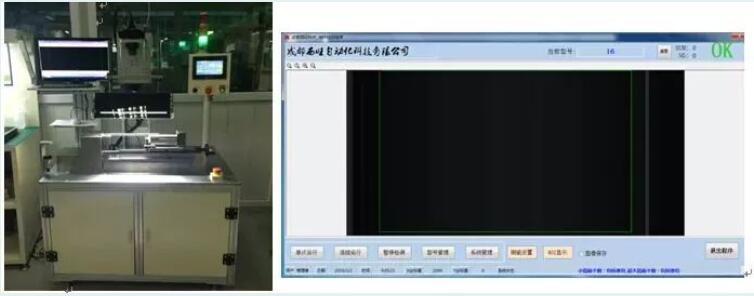

System Performance

The equipment uses an 8K line scan camera with a system's single-pixel accuracy of 0.04*0.04mm. It drives the shock absorber link to rotate using a servo mechanism. During the motion, the line scan vision system captures images of the link's appearance. Image processing software is used to assess whether the link has defects, and the final results are displayed on the equipment's screen. Parameters can also be stored. The entire process is intuitive, clear, and results in good product consistency and reliability.

Control over the equipment's motion is achieved using a (PLC+HMI) programmable logic controller. The servo motor drives the sample's rotation, while the stepper motor adjusts the vertical and horizontal movement of the vision unit to meet the inspection needs of different product models.

Missed Detection Rate: 0%

Defect Detection Rate: 100%

Identification Efficiency: 3 seconds per item

Work Effect

The system has been running stably at the customer's site, and the customer is highly satisfied with the inspection results and the stability of the equipment. The equipment has consistently achieved a yield rate of 99% or higher.

Application Field

Automotive Industry

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu