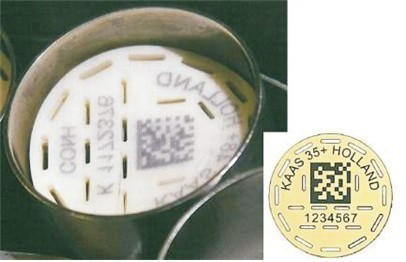

Detection task:

By reading and verifying one-dimensional code and two-dimensional code, the traceability of products in the entire production process and circulation field is realized.

Project introduction:

1. Hardware part: Select 3 hundred thousand pixel camera, use professional visual light source for lighting, adjust the focal length, so that the bar code is clearly displayed on the display.

2. Software part: Use professional visual processing software to output the read one-dimensional code or two-dimensional code and save it into a document.

3. Control part: It can communicate with other equipment (PLC, PC, etc.) to control the culling mechanism or sorting mechanism for culling or sorting.

System performance:

1. System decoding speed up to 90 pieces / s.

2. Real-time database storage of test data, convenient for later review.

3. When defective products are found, real-time audible and visual alarm, controlled shutdown or automatic elimination can be achieved.

4. The system can be customized according to customer needs.

Application field:

Food packaging, pharmaceutical packaging, electronic packaging and other industries that require bar code testing.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu