3.1Background Introduction

In panel manufacturing companies, in addition to the need for alignment and bonding systems, AOI systems are also required to check whether the bonded products are aligned properly. This is generally done by measuring whether the Gap value of the bonded product meets the requirements to determine the quality of bonding. As products become increasingly complex and production volumes grow, many companies lack suitable inspection equipment. Gap measurements are often done manually, and the measurement results are easily influenced by the operator's habits and can vary between different individuals or at different times. This inconsistency in data affects accuracy and slows down the process.

3.2System Performance

The introduction of the New Vision AOI Bonding Gap Detection System addresses the issue of poor consistency in manual measurements and enhances inspection efficiency. This system ensures that each product is inspected, transforming the process from random sampling to full inspection, thus ensuring quality stability throughout the production process. The system utilizes a combination of backlighting and point lighting for illumination, overcoming challenges related to variations in light source brightness and angle, which can lead to inconsistent image contrast. It also addresses issues with edge detection that can be affected by bubbles and excess adhesive. As an example, for Sensor and CG bonding, the system switches between different light sources to capture the edges of CG and Sensor separately. Through the vision system, it calculates the Gap values for each edge and can also determine the center deviation between the two bonded products, providing data for real-time bonding offset correction. This greatly improves production efficiency, product quality, and provides a basis for front-end equipment compensation. The inspection results are displayed on the interface and transmitted to the PLC.

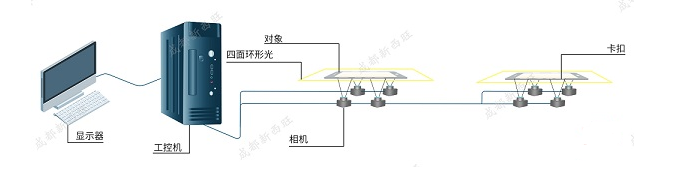

Visual Solution Schematic

False negative rate: 0%

NG detection rate: 100%

Recognition efficiency: 100%

3.3Work Effect

During the production process, this system can efficiently and consistently detect bonded products, determine their quality, and send bonding results and center deviation values to the PLC for compensation at the front end and guidance for back-end material handling. The user-friendly software interface makes it easy for operators to use, and customers are highly satisfied with the system's detection performance and stability.

Application Area

Panel Industry

Bonding Alignment Equipment

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu