Background Introduction

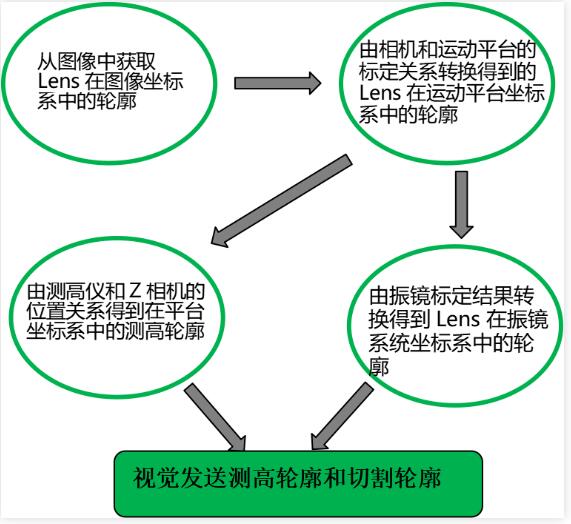

The vision system for the factory's lens production line primarily serves the key process equipment. It includes a comprehensive code-reading and automatic posting system, as well as a full-line BC system (especially for the visual system at stations in the lamination and cutting processes). This system achieves curved surface cutting and curved surface lamination using complex visual algorithm technology. It allows the system to filter out interference and capture contours, even when there are issues such as bubbles, residual adhesive, and chipped corners in the materials.

Core Algorithms

Utilizing distributed edge sampling and applying a third-order curve smoothing process.

The edge detection algorithm employs the summation of the average in the accumulation direction and convolution with an operator conforming to a Gaussian distribution in the search direction to obtain edges.

For candidate edges, the filtering algorithm defaults to providing three scoring strategies for selection: contrast scoring, positional scoring, and sequential scoring.

Application Field

3D Curved Surface Alignment and Lamination Guidance in the Panel Display Industry.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu