Background Introduction

The ACF feeder machine needs to have positioning, AOI (Automated Optical Inspection) functionality, and image storage and upload capabilities while not affecting the UPH (Units Per Hour) to achieve accurate positioning, image storage, and AOI inspection. The AOI inspection is intended to detect white spots, dirt, scratches, and indentations on the Lens surface, with a requirement for a false negative rate of 0% and a false positive rate of less than 2%.

Equipment Features

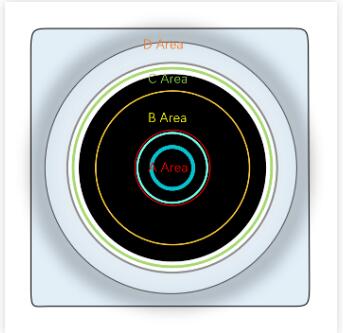

There are four detection areas for Lens, as indicated in the above diagram. The detection types and standards vary for each area, and the product surface characteristics also differ in each area. To ensure compatibility with the accuracy of detection in different areas, the selection of software and hardware presents significant challenges.

Equipment Performance

A Area: Center lens area of Lens, the functional area of the product, capable of detecting white spots, scratches, and dirt, with a minimum defect detection area of 0.003mm².

B Area: Capable of detecting white spots, scratches, and dirt defects, with a minimum defect detection area of 0.003mm².

C Area: Capable of detecting dirt, Barrel-Sim dirt, damage, with a minimum defect detection area of 0.008mm².

D Area: Capable of detecting damage, large area breakage can be detected.

Operational Results

Fast image acquisition: <200ms;

Miss detection rate: 0%;

False positive rate: 1.5%;

Application Field

Panel industry, camera-related processes, etc.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu