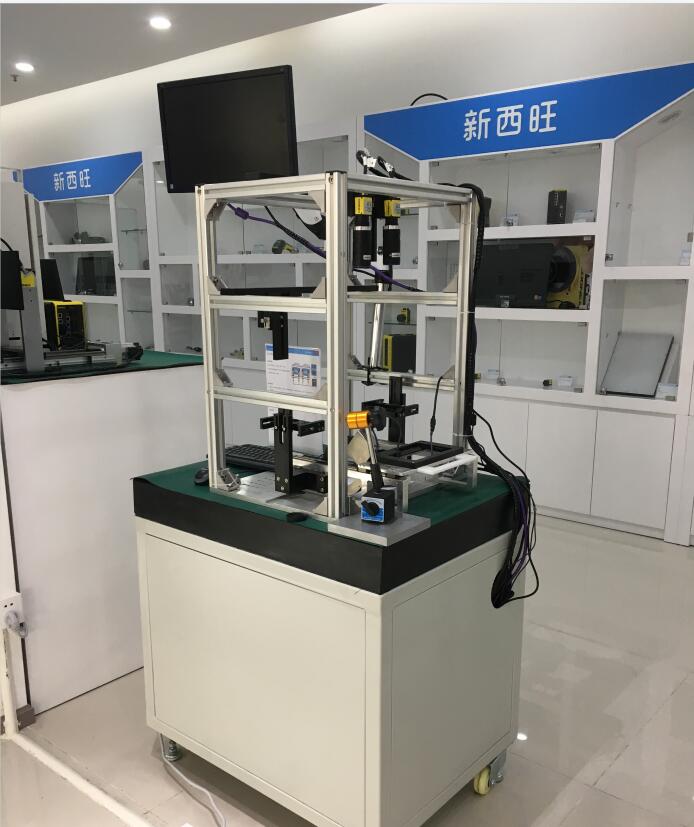

In the machine vision inspection industry, the CCD visual inspection system uses industrial cameras instead of human eyes to complete the functions of identification, measurement, positioning, and judgment. Its application process is as follows:

Functions of CCD visual inspection system:

1. Positioning function: It can automatically locate the position features on the appearance of the inspected product, and if these appearance features are inconsistent with the image coordinates provided by the database during the detection process, the product can be judged to be defective or defective products.

2. Measurement function: It can automatically measure the appearance size of the product, and shoot the product from multiple angles through the CCD camera, and can measure the basic values of the length, width and height of the product, and can also increase the measurement accuracy by increasing the number of CCD cameras and angle adjustment according to different product measurement needs, and measure the size of various shapes and objects at the same time. The corresponding size obtained by the database calculation is compared with the inherent data in the database to determine whether the product size is qualified.

3. Identification function: It can automatically identify the color, graphics, characters, etc. of the product, and judge whether the characters, colors and graphics on the detected product are correct through the database calculation, so as to judge whether the inspected product is qualified.

4. The detection function can automatically detect whether there are some features on the product, and judge the characteristics through the database calculation, and the new features of the inspected products have or exceed the original characteristics to judge whether the inspected products are qualified.

Application process of CCD machine vision inspection system:

1. First of all, the detected object is approached or moved to the center of the field of view of the industrial camera, and if it is, the trigger pulse signal is sent to the image acquisition equipment;

2. The image acquisition equipment sends the starting pulse to the industrial camera and lighting equipment according to the program and delay preset by the designer, but there are also some industrial cameras and lighting equipment that start directly when the system is turned on;

3. The industrial camera stops the current scanning, and then restarts the new frame scanning; Sometimes industrial cameras need to wait before the start pulse arrives, while frame scanning doesn't start until the start pulse arrives;

4. If the strategy used is the exposure strategy, before the industrial camera starts a new frame scanning, the exposure control system should be turned on, and the program or hardware should set the exposure time, exposure speed, and exposure intensity according to your actual needs;

5. If the exposure strategy is adopted, please use another starting pulse to turn on the lighting equipment, especially keep the starting time should match the exposure time, exposure speed, and exposure intensity of the industrial camera;

6. After the industrial camera is exposed, the scanning and output of a frame of image officially begins;

7. If the output of the industrial camera is an analog signal, the image acquisition device will A/D convert the signal received from the industrial camera to digitize it. If the output is a digital signal, the image will be saved to capture the digital signal; Otherwise, the image taken by the image capture device will be saved.

8. The image acquisition device sends the image signal to the data buffer, and then the processor or computer memory is used for image processing and display;

9. The processor or computer processes, analyzes, and recognizes images to obtain measurement results or logic control variables, and then processes them based on these results to control other devices (e.g., mechanical equipment, etc.) to complete relevant actions and perform positioning. Correction of motion errors and rejection defects, e.g. correction of the positioning of the robot arm or sorting out defective products.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu