With the development of the new energy industry and the growing demand for lithium batteries, machine vision inspection technology is increasingly applied to the field of battery production. As a machine vision expert, Xinxiwang is committed to panel display, new energy, semiconductor and other industries, focusing on the design, research and development and production of machine vision systems, and providing overall vision solutions for visual inspection, guidance/alignment, measurement and recognition. The following will explain the advantages of machine vision inspection equipment in the new energy battery testing industry:

1. Accuracy: Due to the limitations of physical conditions of the human eye, the machine has obvious advantages in accuracy. Even if the human eye relies on a magnifying glass or microscope to inspect the product, the machine will still be more accurate.

2. Repeatability: The machine can complete the detection work again and again in the same way without getting tired. In contrast, the human eye will make a slight difference each time it detects a product, even if the product is identical.

3. Speed: The machine can detect products faster. Especially when inspecting objects moving at high speeds, such as on production lines, machines can increase productivity.

4. Objectivity: There is also a fatal flaw in human eye detection, that is, the subjectivity brought by emotion, the detection results will change with the artificial mood, and the machine has no joy, anger and sorrow, and the detection results are naturally very objective and reliable.

5. Cost: Because the machine is faster than human, an automatic detection machine can take on the tasks of several people. In addition, the machine does not need to stop, does not get sick, and can work continuously, so it can greatly improve production efficiency.

New energy battery case:

In recent years, the rapid development of new energy industries such as new energy vehicles, and the demand for power lithium batteries is also growing. As an electric energy storage unit, the quality of the battery cell affects the quality of the entire battery pack, and affects the performance and safety of end products such as electric vehicles. The traditional method of detecting the appearance defects of the battery cell is manual measurement and judgment, which is difficult to meet the needs of the current battery production, and the introduction of lithium battery cell appearance inspection equipment based on machine vision technology is the general trend.

The necessity of using lithium battery cell appearance inspection equipment:

The battery cell is an important part of the lithium battery assembly, which is equivalent to the heart of the lithium battery. The production quality of battery cells is high, the safety factor standard is high, and its production needs to go through dozens of technological processes, a number of quality inspections and production control links.

The traditional method of cell appearance defect detection is manual measurement and judgment, which is affected by the subjective will, emotion, visual fatigue and other factors of the inspector, and the detection results have many fluctuations and uncertainties. For battery manufacturers, they need to take a large risk. The use of lithium battery cell appearance inspection equipment can overcome the shortcomings of manual detection, make the detection results more stable and reliable, save labor costs, and improve the automation degree of the entire production system.

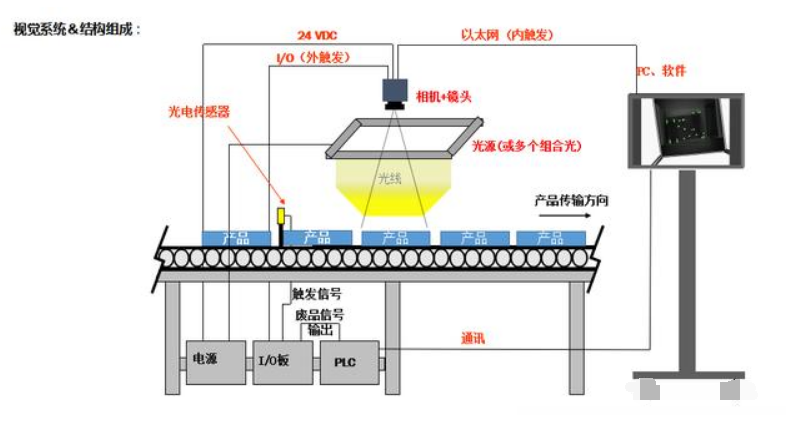

The working mechanism and function of the appearance inspection equipment of lithium battery cells:

The appearance inspection equipment of lithium battery cells is composed of automatic feeding station, cell thickness measurement and tab shaping station, cell appearance 2D inspection station, cell appearance 2.5D inspection station, and automatic blanking station. The manipulator automatically grabs the battery cell from the assembly line and puts it into the cell thickness measurement and tab shaping station, measures the thickness of the product and shapes the good tabs, puts the product into the 2D visual inspection station platform through the mechanical module to detect the front and back of the product, and then puts the product into the 2.5D visual inspection station through the rotating manipulator to detect the front and back of the product. After the completion of the manipulator will put the product into the assembly line, the system will also count the thickness of each product and the results of different items of product testing, and send it to the customer system.

The functions of the device include taking thickness measurements on the cell and detecting the appearance of the cell for undesirable defects such as surface wrinkles, leakage, scratches, etc.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu