In the machine vision inspection industry, the correct lighting method can better identify surface defects. For example: surface detection has always been a difficult point in the machine vision industry, for the detection of scratches and dirt on the surface of polishing materials, common lighting methods are coaxial light, high Angle, low Angle, backlight, etc., the above methods generally have more obvious effects for hard scratches, but some workpiece surface requirements are relatively high, for some soft scratches the effect is often not very obvious. According to our daily work experience, most of the renderings in machine vision are presented by low Angle or high Angle.

For scratches, we propose two solutions based on low Angle and high Angle methods. Industry application: glass, metal, liquid crystal plate, mobile phone screen, plastic and other surface detection. Low Angle method: The machine vision industry often uses a low Angle method for scratch detection.

Before we detect a defect, we first need to understand how the defect is formed, and what reminders and help its formation process have for our work. The formation of scratches is basically due to the direct contact between two objects, resulting in relative displacement due to external forces, resulting in scratches. From the above information shows that scratches are directional. When considering the low-angle lighting effect, if we use a set of light rays parallel to the scratch, the scratch will be blurred by the light, and the effect will not be obvious in the image.

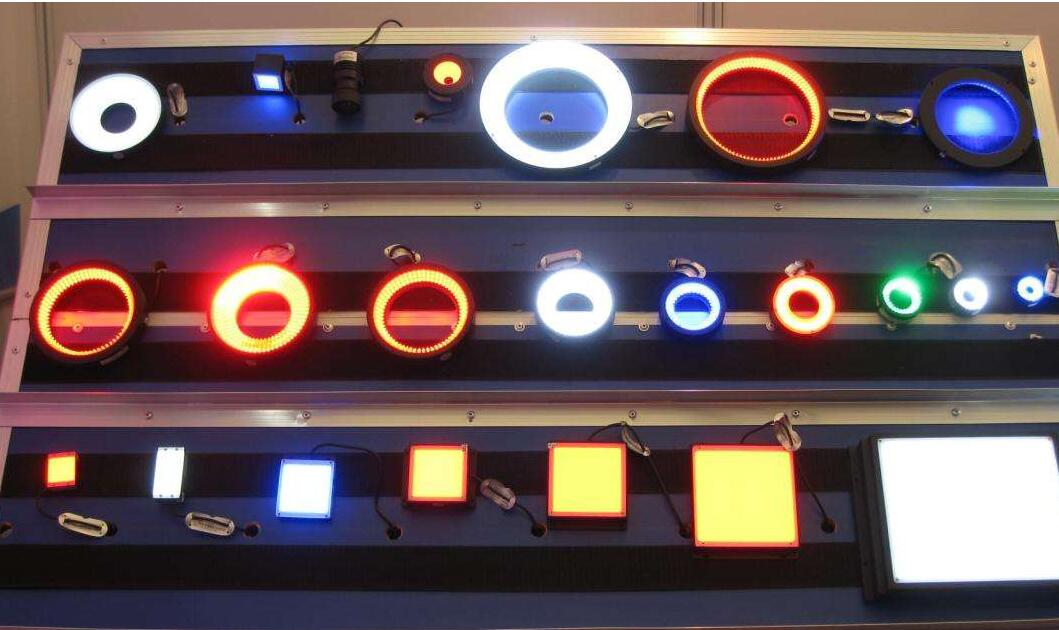

If we shine a beam of light perpendicular to the scratch, the scratch will be highlighted by the light and the effect will be very noticeable in the image. From the above analysis, we use eight strip light source time-sharing exposure workpiece, design the following lighting scheme: a ring light source, divided into eight control, time-sharing exposure, eight consecutive acquisition, after the use of software algorithm, superimpose all defects, and finally detect the surface of the workpiece with a high standard scratch. High Angle mode: According to experience, soft scratches under the coaxial light effect, the higher the working distance of the light source, the more obvious the effect. However, the same light source, the higher the working distance of the light source, the smaller the luminous surface of the light source, the brightness of the light source will also be weakened, and the effect can not be combined with the actual situation.

Chengdu Xinxiwang Automation Technology Co., Ltd. was founded in 2015, is a dedicated panel display, new energy, semiconductor industry, to provide advanced machine vision overall solutions of high-tech enterprises. For more information about machine vision inspection products, you can call the hotline: 028-62705808.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu