Background:

There are many characters on the surface of the electronic chip, including the manufacturer's name, product model, and production time. These characters are of great significance for the manufacture and application of the chip. At present, many of them are completed by manual visual identification, which is easy to be missed by human factors, and the speed is slow and the efficiency is low. In addition to the appearance detection information, it is also necessary to manually measure whether the inductance value of the chip is qualified, and when packaging, it is also necessary to manually check whether the direction of the product is put into the material belt is correct, and statistics are produced on the material belt. These works require a large labor cost, and low reliability, slow efficiency. In order to improve the degree of factory production automation, reduce labor costs and improve production efficiency, improve product quality, how to use an effective intelligent method or technology to quickly and accurately calculate the surface character, inductance value, product packaging and quantity of the chip is an urgent problem to be solved.

System performance:

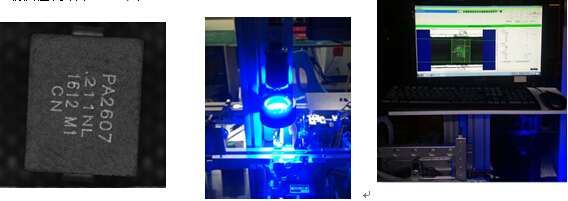

Overall effect: This equipment mainly includes three stations, which are character recognition and positive and negative detection visual station, inductance detection station, automatic packaging station. The overall efficiency is 0.95s/pic; Missed detection rate: 0%; The misjudgment rate is <3%.

Character detection and positive and negative detection station: Cognex vision system and powerful VisionPro software are used to efficiently and accurately detect the character information indicated by the chip and whether the product is inverted when packaging. The image effect is clear and the detection is stable on the high-speed operation pipeline.

Missed detection rate: 0%.

Accuracy: 98%.

Maximum detection efficiency: 0.25s/ piece.

Inductance detection station: Through the high-speed moving transplanting mechanism, the product is accurately placed in the position of the detection instrument to test the inductance value, and the NG product is automatically eliminated. The transplanting speed of the mechanism reaches 1s/pic.

Automatic packaging station: Through the transplanting mechanism to complete the character detection, positive and negative detection, inductance detection products accurately and quickly into the material belt, and the number of packaged products statistics.

Working effect:

In the customer use project, each station of the machine works stably, and the efficient production capacity of 3600 pieces per hour can be reached. The expected effect of high production capacity and high stability has been achieved. There are also great savings in labor costs.

Application field:

Electronics industry or other industries involved in character recognition.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu