A canning company typically produces large quantities of a particular product, such as tomato soup, and then stores it in a warehouse to await customer orders before labeling. Labels on cans are put on before they are shipped, usually with the customer's own brand label. These cans can be transported at a speed of 60 milliseconds each, so it is impossible to perform normal manual inspection. Machine vision solves this problem by connecting a camera to a computer's image-processing card. The downside is that these specialized hardware are not suitable for factory environments. Cameras and image processing cards are easily affected by heat and dust. Setting up and maintaining such systems also requires a considerable level of expertise, which is often lacking in canning plants.

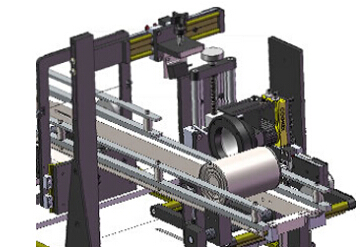

Matrix Technologies has developed a more efficient automatic detection of bright field with the latest machine vision technology. "The key to this new approach is that the Cognex In-Sight 5600 vision system can detect product codes against a bright background at a rate of 1,000 items per hour." Les Haman, division manager at Matrix Technologies. Cognex PatMax image matching tool can detect product codes. Using the PatMax tool, the program can recognize images from any location. The program does not read individual characters. You can configure it to search for images that match the three product codes. Just place the new code on the can and the vision system detects the position and places a rectangle around the product code, and the new product code is configured. From this point of view, even if the product code is in another position or another Angle, as long as it is within the detection field of view, the vision system can detect the product code. This approach is simpler, more reliable and more economical than traditional machine vision techniques used in the past.

Matrix Technologies' bright stock label solution also uses a laser scanner to read barcodes on product labels. Fiber optic sensors can determine whether the label has been correctly attached to the can by detecting any protrusions.

Matrix Technologies is deploying 10 of these systems for its first customers. "Two of them have been deployed and are running, and they're doing pretty well." Haman concluded. "bright stock label solutions have proven the accuracy of their detection and are almost never down. It has been proven that matching product code images directly is a more stable and reliable solution than converting images to characters. Current factory workers can maintain these devices without difficulty, or program them to read new product codes. Based on performance standards, benchmarks, and user recognition, this solution offers attractive value for bright stock testing in the food and beverage industry."

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu