Arndt Fenstertechnik GmbH & Co. KG from Dusseldorf, Germany, combined these two strengths in its new cutting center, where Cognex's incredibly small and powerful In-Sight® Micro 1100 vision system made a great contribution.

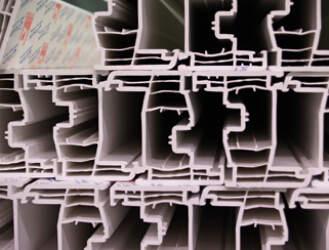

Stricter insulation regulations and rising energy prices are driving demand for plastic Windows. Plastic has good thermal and sound insulation properties, and the maintenance cost is low. Even from an aesthetic point of view, plastic Windows are more popular than wooden Windows and aluminum Windows because of the rich color and design. Increasing variety and expanding demand require the production line to be more flexible while increasing output.

Just before completing the planning phase of the new cutting center, Arndt Fenstertechnik realized that there was a problem with one of the first steps of the process in the feed area. Misplaced board components can damage production lines and lead to costly shutdowns. Hundreds of different window frame material types need to be accurately identified in seconds.

The company began looking for reliable, low-cost solutions to optimize this important step. After further research, they chose to collaborate with Peter Scholz Software+Engineering GmbH in Weiden, Germany and were equipped with the In-Sight Micro 1100.

100 profiles in seconds

The central IT unit instructs the operator which pipe should be placed on the conveyor belt. The In-Sight vision system recognizes the material cross section and matches it with previously programmed data to ensure the appropriate hose is placed in place. Window frame materials differ in terms of external contours and internal cavities, while most materials differ only in size.

The smart vision system, which only measures 30mmx30mmx60mm, guarantees up to 100 material switches per day to maintain a reliable production process. Equipped with the VisionView® user interface, operators can monitor the current production process.

Easy training for high speed cycles

In-Sight Micro 1100 is a standalone vision system. Only a PC is needed to "teach" the new material. Arndt Fenstertechnik wanted to network the vision system with the company's central IT system so that authorized employees could access the vision system from any PC in the network.

Arndt Fenstertechnik is able to make his employees understand the importance of maintaining and installing new material data. As the broad product portfolio of window frame materials continues to grow, the need to minimize the cost of frequent reprogramming becomes increasingly urgent. One of the strengths of the In-Sight Micro 1100 is its EasyBuilder® configuration software. New material detection patterns can be programmed with just a few keystrokes. The intuitive, user-friendly interface guides the user through the setup process to complete the entire application. When configured, the In-Sight Micro 1100 guarantees fast cycling and correct component input without any PC input, enabling the successful production of window frames and making this line one of the fastest in Europe.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu