Background Introduction

In the panel assembly industry, the cover glass of mobile phone screens (Cover glass) requires the lamination of a protective film during the production process to prevent screen scratching.

System Performance

Xinxiwang's high-precision alignment and lamination system uses automatic hand-eye calibration and joint calibration to calibrate the alignment devices of multiple cameras and equipment on the system in the same coordinate system, providing precise alignment guidance for the lamination of protective film in a stable and efficient manner. During application, the system evaluates the motion error of the alignment platform based on the translation and rotation calibration results from the hand-eye calibration. The final product lamination accuracy is ±0.15mm, and various error prevention controls are added, including product size control, loading accuracy control, and alignment control (to ensure products do not press on fixtures). These control values can be modified as needed.

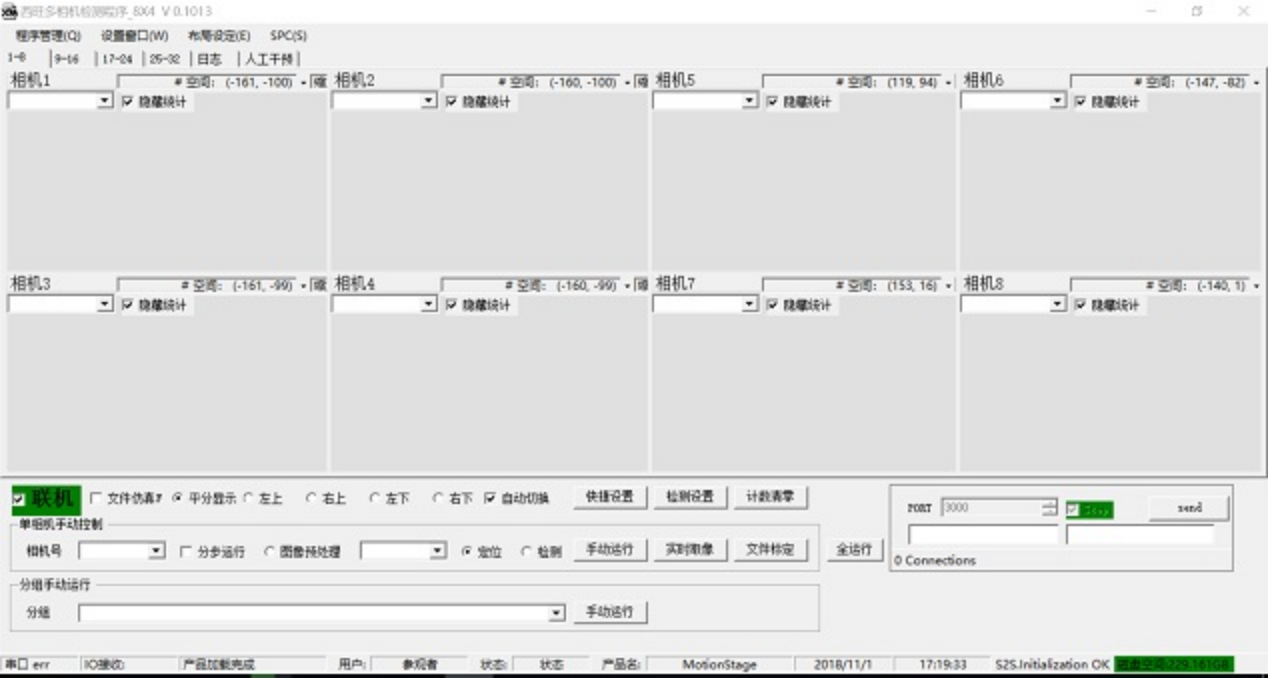

Software Interface Diagram

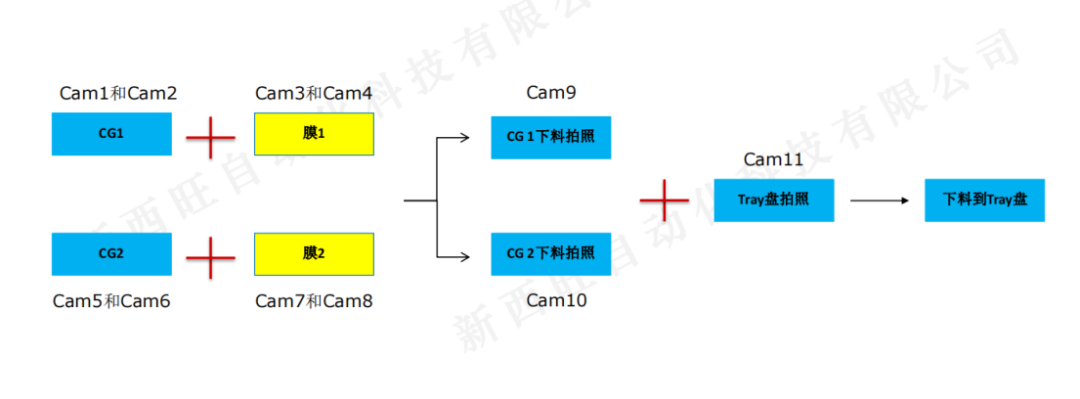

Visual Solution Conceptual Diagram

Single Alignment Accuracy: ±0.015mm;

Single Alignment Precision: 99.9%

Number of Cameras in the System: 11 CCDs;

Application Equipment: Protective Film Lamination Equipment;

Operational Results

This system, used in protective film lamination machines, ensures stable lamination of protective films and accurate positioning for CG unloading.

Application Field

Protective film lamination in the panel industry.

Phone:028-62705808

Fax:028-62705808

Mobile Phone:18215640190

Email:sales@cdxiwang.com

Address:2-8-6, Chen Electric Technology Innovation Park, 68 Shuangbai Road, High-tech West District, Chengdu